Bio-based thermoplastic Polyurethane (TPU), also named bio-based polyurethane, has gained a lot of attention in recent years. However, it is possible that ester bond hydrolysis could occur during its usage. Hydrolysis means the chemical chain is broken under the influence of water. This problem can be solved by adding carbodiimide. We will share this information in the content below.

What is Bio TPU?

Bio-based thermoplastic polyurethane is an elastomer made from renewable resources.

TPU is renowned for its high-quality properties, such as flexibility, mechanical strength, and abrasion resistance. TPU is used in many industries, including automotive, footwear and electronics, due to its versatility.

TPU is traditionally produced using petrochemicals, which is not good for the environment. Bio-based TPU have gained more attention to counteract this. Bio-based TPU is made from renewable resources such as vegetable oils, starch or biopolyols, instead of petrochemicals.

Bio-based TPU

Bio-based TPU has many similar mechanical properties as traditional TPU, but also offers additional benefits such as a reduced carbon footprint. It is also more sustainable. It is 100% recyclable and can also be disposed in an environmentally friendly way.

The bio-based TPU material is made by polymerizing biologically derived materials. These materials have excellent mechanical properties and are resistant to chemicals. They can be used in a variety of applications including footwear, performance film, medical equipment and automobile exterior and interior components.

The disadvantage of bio-based TPU

The ester bonds of TPU are susceptible to attack by water molecules (see more about hydrolysis), causing the polymer chain to break. This reduces the lifespan of the product. This is due to hydrogen bonds forming between water molecules, and ester bond, making the ester bonds hydrophilic.

Application carbodiimide as an anti-hydrolysis agent for bio-based TPU

In this context, carbodiimide has gained increasing attention. When added to bio-based TPU as an anti-hydrolysis agent, carbodiimide can enhance its hydrolysis resistant.

Carbodiimide has a rationale: it can undergo cyclization preferentially with ester bonds. This produces a stable cyclized products, “pre-emptively”, occupying the positions where water molecules attack carbonyl groups, and blocking further attacks by water molecules.

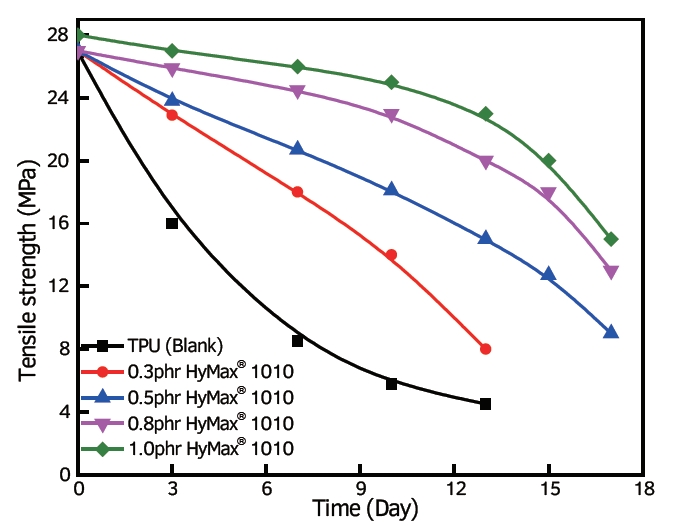

Studies have shown that adding a suitable amount of carbodiimide can significantly increase the hydrolysis resistance and thus extend the lifespan of bio-based TPU. The impact of carbodiimide is minimal on other TPU properties, including hardness and elongation.

The effect of anti-hydrolysis agent in TPU

Bio-based thermoplastic Polyurethane (TPU), a renewable resource elastomer, is an environmentally friendly material with excellent mechanical properties. The addition of carbodiimide, despite its susceptibility for hydrolysis that can shorten the lifespan of bio-based TPU, significantly increases its resistance to hydrolysis. This allows it to be used longer and preserve its key properties such as hardness, and elongation. Carbodiimide is therefore an excellent solution to mitigate hydrolysis issues in bio-based applications.