Both PET and PBT are polyesters.

PET has a highly compact molecular structure and a certain plastic synthesis ability, so it has good non-film and film-forming properties.

In addition, PET plastic has excellent wear resistance, friction, size and stability. Bottles made of PET have high strength, good transparency, non-toxicity, anti-permeation, light weight, and high production efficiency, which are widely used.

But the fatal shortcoming of PET is that its hygroscopicity is relatively high, and under wet conditions, the characteristic bonds in the molecule are prone to shrink and recover, resulting in a decline in overall performance and an extension of life.

PBT molecular chain structure and many characteristics are similar to PET, but its electrical insulation and durability are more common, so it is used for electronic and electrical shells, parts shells, mechanical equipment shells, automobiles, etc.

The hygroscopicity of PBT is relatively low, but it is also not prone to problems under humid and hot conditions.

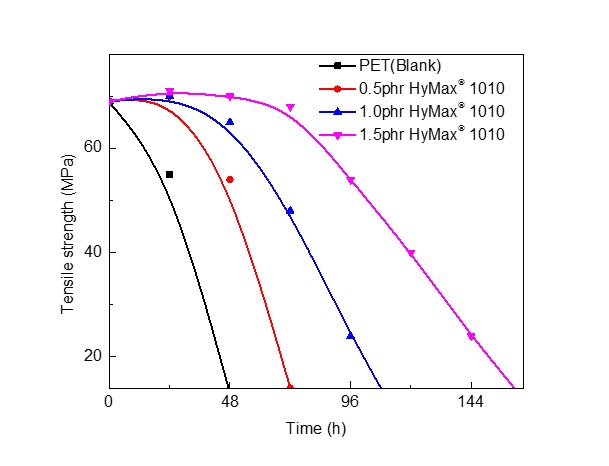

HyMax® 1010 can significantly improve the hydrolysis resistance of PET materials, especially if the addition amount is ≥1.0%, as the addition amount increases, the hydrolysis resistance performance improves.

We will contact you within 1 working day, please pay attention to the email with the suffix “@langyitech.com”.