Both PLA and PBAT are widely used biodegradable plastics. PLA is formed by the self-condensation of polylactic acid, and PBAT is formed by the ternary copolymerization of terephthalic acid, adipic acid, and 1,4-butanediol. The raw materials of PLA and PBAT can be obtained from natural starch, which has good biocompatibility. PLA and PBAT can be completely degraded by microorganisms to generate carbon dioxide and water without polluting the environment. They are recognized as environmentally friendly materials.

PLA has good tensile strength and ductility, can be produced by various common processing methods, and its products also have some unique properties. For example, PLA film has good air permeability, oxygen permeability and carbon dioxide permeability, and also has the characteristics of odor isolation; PLA 3D printing wire has low shrinkage rate, high precision, low melting point, and does not release toxic or irritating gas during printing.

PBAT combines the characteristics of PBA and PBT, not only has good ductility, elongation at break, heat resistance, and impact resistance but also has excellent biodegradability. It is currently very active in the research of biodegradable plastics and one of the best degradable materials for market applications. The end product is usually made by blending and modifying PLA and PBAT resin. The main markets of PBAT are plastic packaging films, agricultural films, disposable plastic bags and disposable plastic tableware.

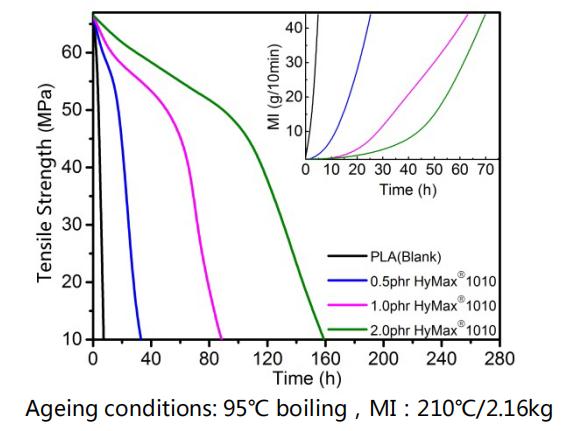

Both PLA and PBAT contain ester groups. They are prone to hydrolysis in a humid and hot environment, which affects their mechanical properties and service life.

HyMax® 1010 can make the carboxyl groups of PLA and PBAT form end caps, and the carboxyl groups are the main cause of hydrolysis.

HyMax® 1010 can increase the hydrolytic stability of polylactic acid (PLA) by 2 to 3 times. Depending on the added amount and test conditions, the service life of PLA and PBAT can be increased by 3 to 7 times.

HyMax® 1010 can extend the chain during the processing of PLA or PBAT. The polymer short chain and long chain recombine together, but it does not cause the problem of broadening the molar mass distribution (polydispersity) caused by traditional chain extenders.

In this way, HyMax® 1010 improves the molar mass of PLA or PBAT and keeps the product’s mechanical properties in an appropriate range.

We will contact you within 1 working day, please pay attention to the email with the suffix “@langyitech.com”.