Polyurethane is a type of polymer material with special properties. It combines the performance characteristics of various materials from plastics, elastomers to coatings, such as a wide range of hardness, high strength, wear resistance, good vibration absorption, radiation resistance, and resistance to Breathability, good processing properties, etc., so it is widely used, such as polyurethane foam materials, polyurethane elastomers, polyurethane waterproof materials, polyurethane coatings, polyurethane adhesives, biomedical materials, etc.

The polyurethane main chain contains repeating carbamate groups. The ester groups are sensitive to heat and moisture, and are prone to hydrolysis to cause molecular chain scission. The carboxylic acid produced by hydrolysis will further catalyze the hydrolysis of the ester groups and ultimately cause the overall performance of polyurethane to decrease The shortening of service life affects the application of materials.

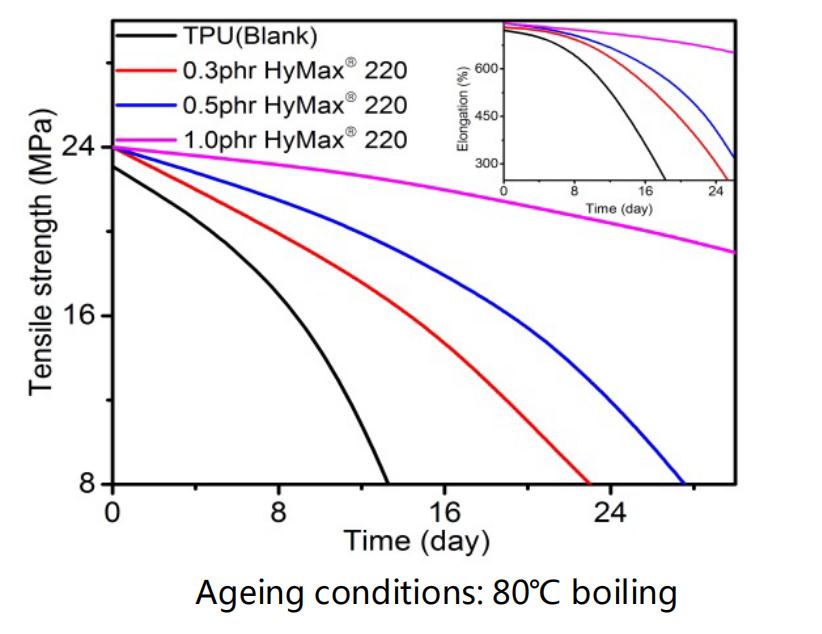

HyMax® 1010 and HyMax® 220 are both carbodiimide compounds. As a class of high-efficiency polyurethane anti-hydrolysis agents, they can react with polyurethane hydrolysate carboxylic acid or water to prevent further autocatalytic hydrolysis and improve polyurethane compounds. The comprehensive performance and service life, especially the improvement of hydrolysis resistance under high temperature and humidity conditions.

HyMax® 220 can significantly improve the anti-hydrolysis resistance (tensile strength, elongation, melt viscosity and acid content) of TPU, polyester polyurethane adhesives, and polyurethane shoe-sole systems based on polyester polyols.

We will contact you within 1 working day, please pay attention to the email with the suffix “@langyitech.com”.