Renewable biobased polyester monofilament has quickly become one of the go-to sustainable development materials due to its environmental protection properties and outstanding performance, but like traditional polyester materials it does experience hydrolysis.

1. Development and Advantages of Renewable Biobased Polyester Monofilament Fabrics

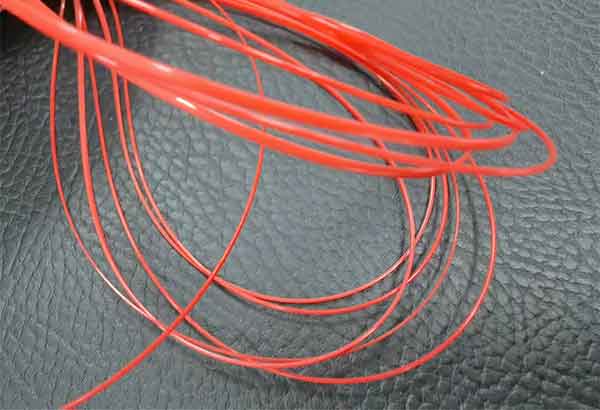

With increasing concern for environmental preservation, renewable biobased polyester monofilament has gained increasing attention as an eco-friendly material. Composed primarily from biobased raw materials like plant starch and cellulose, it undergoes chemical treatment processes before becoming monofilaments boasting strength, toughness and wear resistance.

Comparative to synthetic polyester monofilament, renewable biobased polyester monofilament offers several significant advantages:

Environmental protection and sustainability: Reducing our dependence on non-renewable resources like petroleum while decreasing carbon emissions falls under the umbrella of “green development.”

Superior Performance: With outstanding strength, toughness, wear resistance and other properties that meet various application needs. 3. Biodegradability: Microorganisms can decompose it under specific conditions to reduce pollution in the environment.

2. Impact of hydrolysis on biobased polyester monofilament

Renewable biobased polyester monofilament offers many advantages, but can also be vulnerable to hydrolysis in humid environments. Water molecules attack ester bonds in polyester monofilaments, leading to molecular chain breakage and reduced performance – thus diminishing performance over time. Here are its key manifestations:

1. Decrease in Strength: Hydrolysis can gradually weaken monofilament tensile strength and breaking strength, decreasing its reliability during use.

2. Deterioration of Toughness: Hydrolysis will make monofilaments increasingly brittle and hard, losing their original toughness and becoming easily broken.

3. Reduction in Dimension Stability: Hydrolysis could cause monofilament expansion/contraction thus altering product dimensions significantly.

4. Shortening Service Life: Hydrolysis will dramatically shorten the service life and use cost of biobased polyester monofilament, leading to reduced productivity in production facilities and increasing use costs.

3. Mechanism of anti-hydrolysis agents

Anti-hydrolysis agents have become a widely utilized way of combatting biobased polyester monofilament hydrolysis issues, and their mechanism of action typically consists of two points.

Blocking End Groups: Anti-hydrolysis agents can react with the end groups of polyester monofilament molecules to block them and prevent further water molecules from attacking.

Forming Stable Chemical Bonds: Anti-hydrolysis agents can form stable chemical bonds with ester bonds present in polyester monofilament molecules, increasing molecular chain stability while minimizing hydrolysis events.

4. Methods for adding anti-hydrolysis agents in biobased polyester monofilament materials

Powder addition: it is more complex and can have upper limits on its addition amount; Masterbatch addition: it is relatively more convenient and ensures uniform distribution of anti-hydrolysis agents in monofilaments.

5. Common Types and Characteristics of Anti-hydrolysis Agents

Anti-hydrolysis agents typically come in either monomeric or polymeric varieties. Monomeric anti-hydrolysis agents tend to have lower costs but comparatively weaker anti-hydrolysis effects while polymeric ones offer stronger ones at greater costs. When selecting an anti-hydrolysis agent, factors like cost and performance must be carefully considered in order to select an ideal type.

6. Potential Application of Anti-hydrolysis Agents in Renewable Biobased Polyester Monofilament

With rising environmental awareness and requirements of sustainable development, renewable biobased polyester monofilament applications have expanded steadily over time. Anti-hydrolysis agents will further enhance its performance and stability for wider application in various fields.

Biobased polyester monofilament can be used in textile manufacturing to produce high-performance fabrics such as sportswear and outdoor equipment, with anti-hydrolysis agents used to prolong fabric durability and service life, fulfilling consumer demand for superior-grade products.

Industrially, biobased polyester monofilament can be used to produce ropes, fishing nets, filter cloths and filter media. With anti-hydrolysis agents added, performance and stability can be significantly increased in humid environments while maintenance costs decrease considerably.

7. Conclusion

Overall, anti-hydrolysis agents in renewable biobased polyester monofilament have immense significance. By selecting appropriate types and addition methods of anti-hydrolysis agents, their anti-hydrolysis performance of biobased polyester monofilaments can be improved significantly, their service lives prolonged, and application scope broadened significantly. Furthermore, as technology continues to advance and innovate rapidly, their use will only become increasingly extensive making significant contributions towards sustainable development.