Starch-based plastics are a type of biodegradable plastic made from renewable resources such as corn, potatoes, and cassava. They are considered to be environmentally friendly because they can be degraded into natural compounds under certain conditions, such as exposure to water, heat, and microorganisms. Compared to traditional petroleum-based plastics, starch-based plastics have lower environmental impact and are becoming increasingly popular in various applications.

There are several applications of starch-based plastics, including:

Packaging materials such as bags, films, and containers. They are suitable for food packaging because they are safe and biodegradable.

Agricultural applications: Starch-based plastics can be used in agricultural applications such as mulch films, seedling pots, and nursery trays. They can help to reduce environmental pollution caused by traditional plastics and provide a sustainable alternative.

Medical applications: Starch-based plastics can be used in medical applications such as surgical implants and drug delivery systems. They are biocompatible, which means they are less likely to cause an immune reaction in the body.

Consumer goods: Starch-based plastics can be used in consumer goods such as toys, office supplies, and electronics. They can provide a sustainable alternative to traditional plastics and reduce the environmental impact of these products.

However, the rapid degradation of starch-based plastics in natural environments has limited their widespread application. To address this issue, the use of hindered phenols such as carbodiimide as an anti-hydrolysis agent has been explored to enhance the performance of starch-based plastics.

Carbodiimide is a type of hindered phenol antioxidant that can effectively stabilize the molecular chains of starch-based plastics and slow down the oxidation and hydrolysis reactions that occur in natural environments. The addition of carbodiimide can significantly improve the mechanical properties of starch-based plastics, such as tensile strength and elongation at break, and increase their resistance to water and heat. Moreover, the use of carbodiimide can also prolong the shelf life of starch-based plastics and increase their service life.

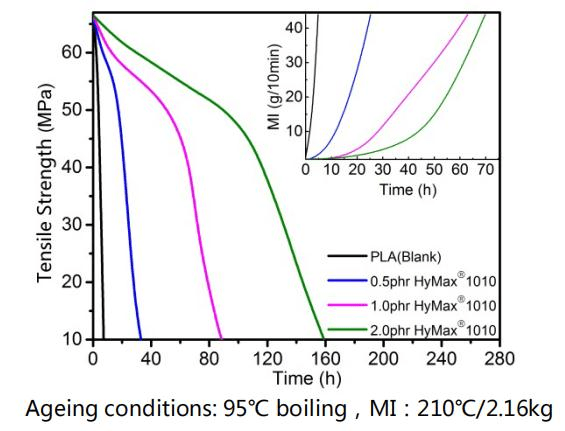

See the testing effect of HyMax products in PLA

HyMax 1010 and HyMax 210 are two types of carbodiimide anti-hydrolysis agents developed and manufactured by Langyi Functional Materials Co., Ltd. Langyi, as a high-tech company, has more than 10 years of experience in the application of carbodiimide anti-hydrolysis agents in biodegradable area. The HyMax products have been successfully applied in various fields such as plastic packaging, straws, and agricultural mulch films. If you are interested in our products or need a sample for test, feel free to contact us.