Polyurethane polymer materials have the advantages of wear resistance, high temperature resistance, good adhesion, easy processing and favorable price. Water-based polyurethane (WPU) uses water as the dispersing medium, avoiding the disadvantages of traditional organic solvents such as serious pollution and health hazards, while saving a large amount of organic solvents and greatly reducing costs. Due to the advantages of non-combustibility, high safety and easy modification, water-based polyurethane is widely used in coatings, adhesives, fabric finishing agents and coating agents, etc. Polycarbodiimide crosslinker can significantly improve the performance of waterborne polyurethane in these applications with a small addition.

Waterborne polyurethane leather finishing agents

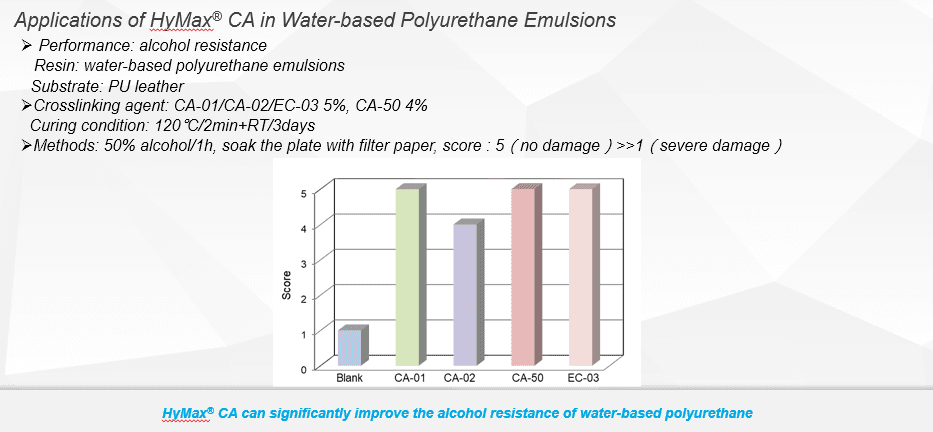

Polyurethane resin is flexible and wear-resistant, and it can be used as coating agent and mending agent for natural leather and artificial leather; water-based polyurethane coating agent overcomes the weakness of acrylic emulsion coating agent of “hot, sticky, cold and brittle”. The leather treated with PU finishing feels soft, smooth, rich and shiny, with a strong sense of leather, which can greatly improve the grade of leather goods and enhance the competitiveness of the market. It can greatly improve the quality of leather goods and enhance the competitiveness of the market. The addition of carbodiimide cross-linking agent in water-based polyurethane can significantly improve the abrasion resistance, water resistance and solvent resistance.

Waterborne polyurethane coatings

Solvent-based polyurethane coatings are a high-grade coating, but conventional solvent-based polyurethane coatings contain about 40% organic solvents. Therefore, the VOC (Volatile Organic Compounds) of coatings bring huge pollution to the atmosphere. With the increase of environmental requirements, solvent-based coatings are gradually replaced by environmentally friendly coatings, mainly including high solids coatings, water-based coatings, powder coatings and radiation curing coatings. Among them, water-based coatings are the most important category.

Currently, waterborne polyurethane dispersion-based coatings are widely used for wood, metal and plastic substrates. The addition of carbodiimide crosslinkers to waterborne polyurethane coatings significantly improves the peel strength, resulting in longer life of the molded coating and higher tolerance to water and alcohol.

Waterborne polyurethane adhesives

Water-based polyurethane adhesive (PU adhesive for short) is an adhesive made of water-based polyurethane, which is an important class of water-based adhesive and has been developed rapidly in recent years for its excellent adhesion, outstanding oil resistance, impact resistance, abrasion resistance, low temperature resistance and other characteristics.

Compared with solvent-based polyurethane adhesives, water-based polyurethane adhesives are green and environmentally friendly products that can be used in many fields and on a variety of substrates. Most water-based polyurethane adhesives are linear thermoplastic, which, together with the hydrophilic groups in their molecular chains, result in poor water and heat resistance. The addition of carbodiimide crosslinkers to waterborne polyurethane adhesives can significantly improve this disadvantage.