When you feel that scorching heat on a sunny day, do you ever wonder what's causing it? It's often infrared light, and finding materials to block it is a big challenge.

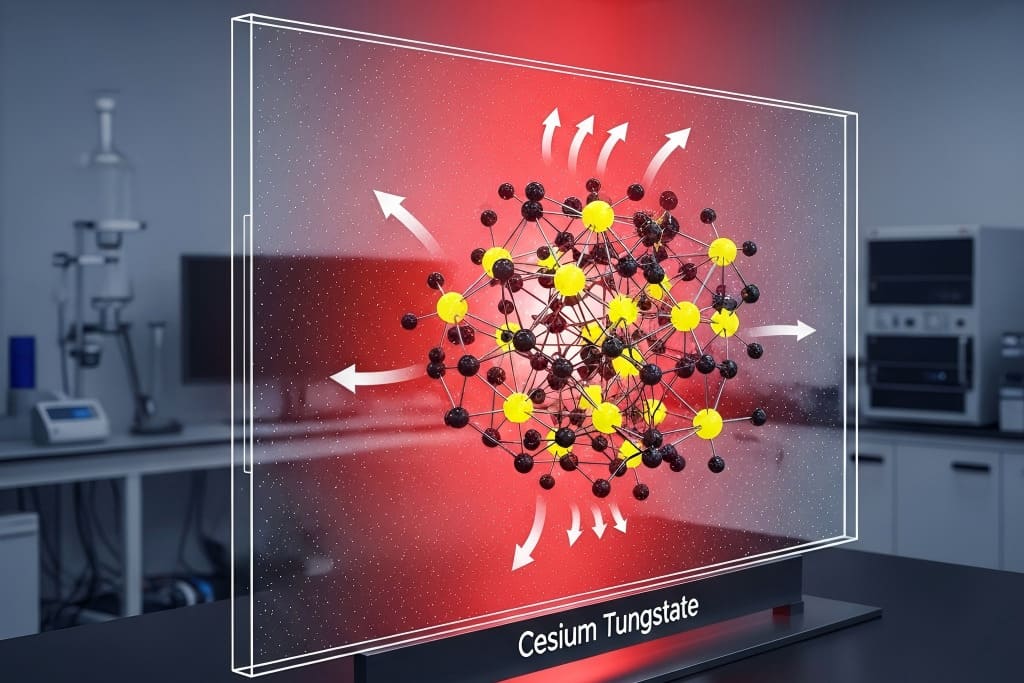

Cesium tungstate is a superior infrared blocking material due to its unique crystal structure and electronic properties that efficiently absorb and scatter infrared radiation1, making it ideal for various thermal management applications2.

As someone who has been with Langyi for 15 years, I've seen firsthand how crucial effective materials are, and I want to share some insights with you about why cesium tungstate stands out in blocking infrared light.

What Material Blocks IR?

Are you looking for ways to keep things cool by stopping infrared light? Many materials can do this, but they work in different ways and with different levels of success.

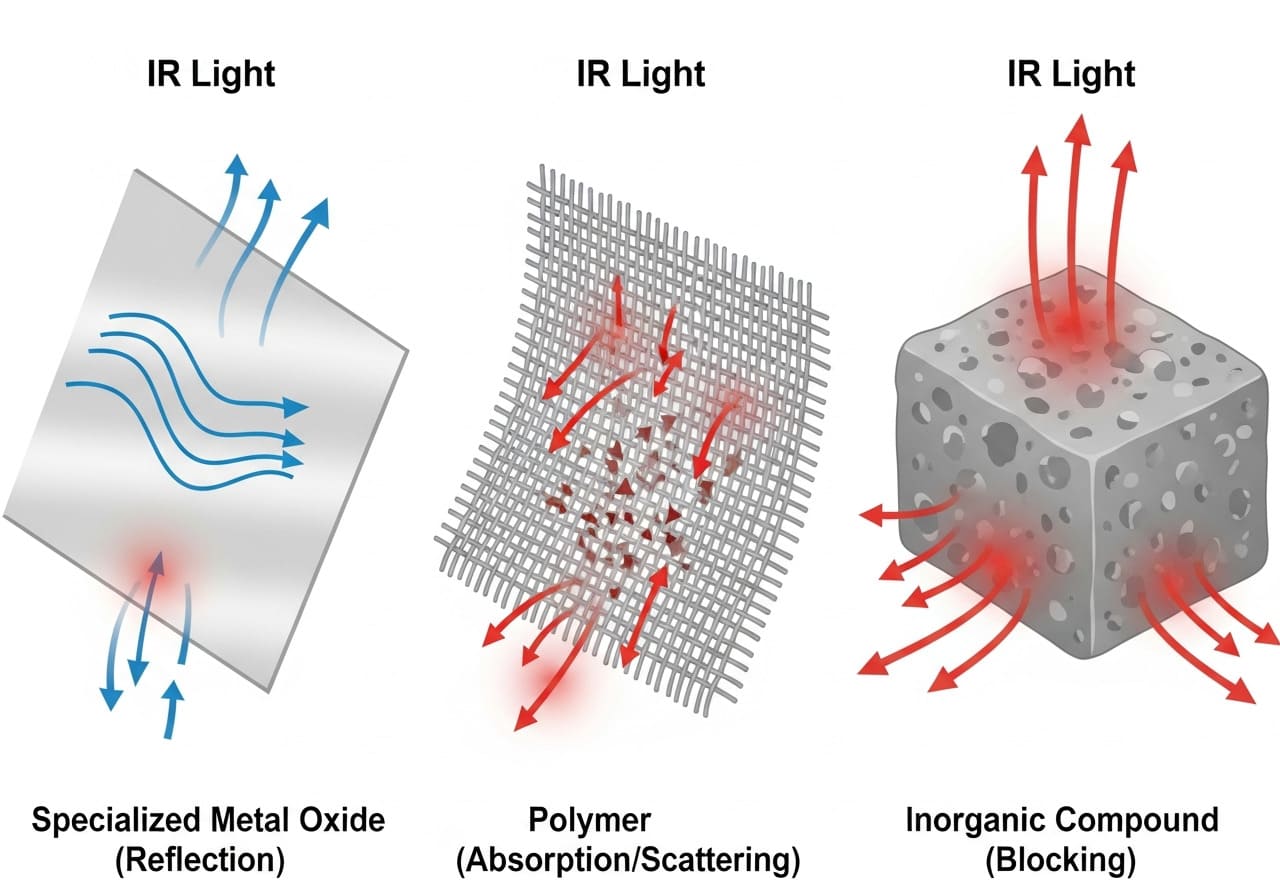

To effectively block infrared (IR) light, materials typically rely on properties like high absorption, reflection, or scattering within the IR spectrum, with some common examples including specialized metal oxides, polymers, and certain inorganic compounds.

At Langyi, our mission is to provide functional additives that solve specific problems. We often get questions about the best materials for IR blocking. Based on our experience and Dr. Tang's expertise, I can tell you that while many materials try to block IR, very few do it as effectively and efficiently as cesium tungstate.

How Different Materials Tackle Infrared?

Infrared radiation is a form of electromagnetic energy that we often feel as heat. Blocking it means either stopping it from passing through a material or sending it back where it came from. Different materials use different strategies. For instance, some materials reflect the IR light away, much like a mirror reflects visible light. This is common in reflective coatings on windows. Other materials absorb the IR light. When a material absorbs IR, the energy often turns into heat within the material itself. This can be useful in some cases but not in others if you want to keep the object cool. Some materials can also scatter infrared light. Scattering means the light does not pass straight through but gets sent in many random directions. This reduces the amount of IR light that goes in one direction.

Common IR blocking materials include:

| Material Type | Primary Mechanism | Examples | Typical Applications |

|---|---|---|---|

| Metal Oxides | Absorption, Scattering | Indium Tin Oxide (ITO), ATO | Smart windows, transparent coatings |

| Polymers with Additives | Absorption, Reflection | Specialized PVC, PET films | Packaging, agricultural films |

| Rare Earth Compounds | Absorption | Lanthanum Hexaboride | Automotive glass, energy-saving films |

| Tungstates | Absorption, Scattering | Cesium Tungstate | Solar control films, heat-insulating coatings |

Each material has its pros and cons. For example, some metal oxides found in smart windows3 work well but can be expensive or hard to process. Polymers with additives are more flexible but might not offer the same level of performance. This is why choosing the right material is a big decision based on what you need it for.

Mechanism: How to Block Infrared Light?

Have you ever wondered how some materials stop heat without blocking light? It’s not magic; there's a science to it, especially when it comes to infrared light.

Materials block infrared light primarily through three mechanisms: absorption, reflection, and scattering, with the most effective materials often utilizing a combination of these to reduce the transmission of specific wavelengths of IR radiation.

As a material scientist, Dr. Tang always emphasized understanding the core mechanisms. It's not enough to know what blocks IR; you need to understand how it happens to create better solutions. This scientific understanding is at the heart of Langyi's approach to developing functional additives.

Decoding the Science of Infrared Blockade?

Infrared radiation is a part of the electromagnetic spectrum4, just like visible light, but with longer wavelengths. We feel it as heat. When infrared light hits a material, it can do one of three things: pass through (transmit), bounce off (reflect), or be taken in (absorb). To block IR, we want to maximize reflection or absorption and minimize transmission.

- Absorption: This is when the material takes in the energy from the infrared light. When a material absorbs IR light, the energy excites the molecules within the material, making them vibrate more. This added energy usually turns into heat within the material. For example, a dark surface absorbs more sunlight (including IR) and feels hotter. Materials like certain semiconductors or metals with free electrons are good at absorbing specific IR wavelengths. Cesium tungstate is excellent at absorbing near-infrared (NIR) due to its unique electronic band structure.

- Reflection: This is when the infrared light bounces off the surface of the material. Think of a mirror; it reflects visible light. Certain coatings, especially those with metallic properties or specific physical structures, can reflect a large portion of IR radiation. These are often used in "cool roof" technologies or thermal blankets. The material's surface properties and refractive index play a big role in how much IR is reflected.

- Scattering: This happens when the infrared light hits small particles within a material and is redirected in many different angles. Instead of passing straight through, the light is dispersed. This makes the material look hazy or opaque to IR light. Nanoparticles are particularly effective at scattering. For example, if you have very tiny particles spread throughout a clear film, they might scatter IR light away while still letting visible light pass through. This is a key mechanism for many advanced IR-blocking films.

Cesium tungstate's effectiveness comes from its ability to strongly absorb and scatter near-infrared radiation. Its unique crystal structure allows for a strong interaction with these wavelengths, making it a powerful choice when you need to significantly reduce heat transmission. My experience tells me that understanding these mechanisms is what allows us to truly master material solutions.

Application of Cesium Tungstate (Powder Form, Liquid Form, Masterbatch Form)?

Are you wondering how a powerful IR-blocking material like cesium tungstate goes from a chemical compound to a usable product? The form it takes is crucial for how it's applied.

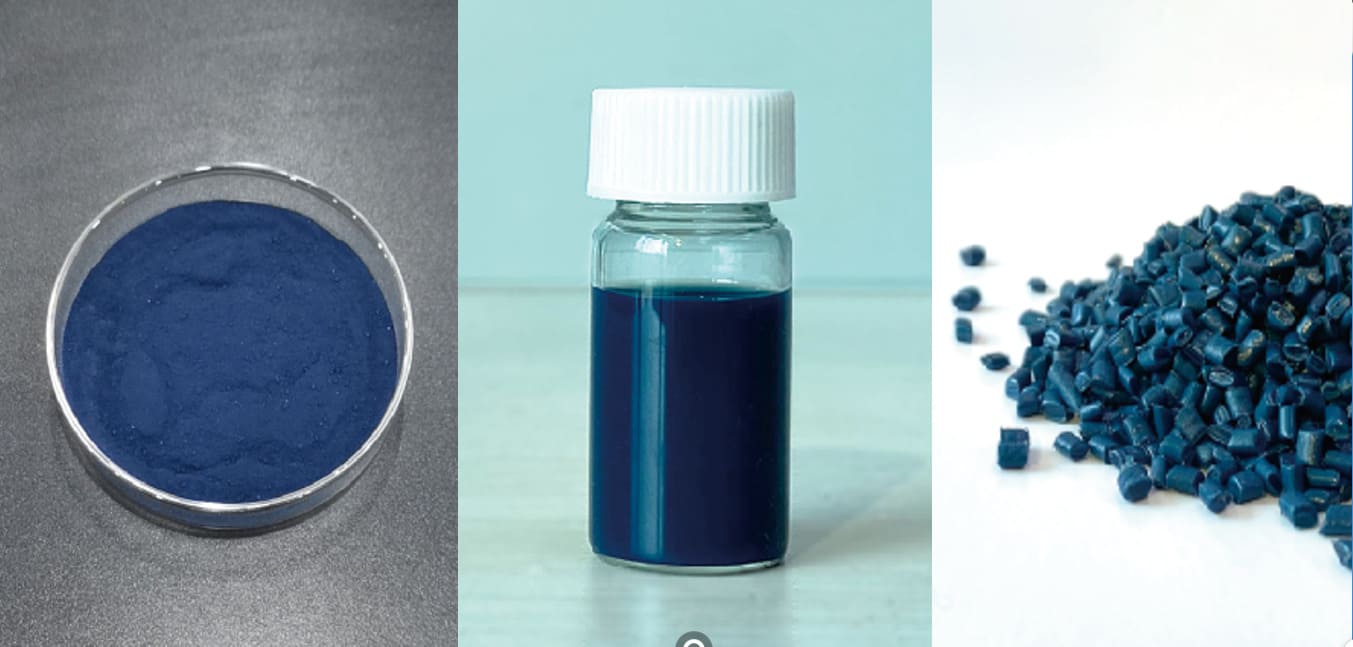

Cesium tungstate is versatile in its application, available in powder, liquid dispersion, and masterbatch forms, each tailored for different manufacturing processes to efficiently integrate its IR-blocking properties into various end products like films, coatings, and plastics.

At Langyi, we often work with our clients to determine the best form of cesium tungstate for their specific needs. From raw powder for precise formulation to ready-to-use masterbatches, the way it's presented makes a big difference in the final product's performance and ease of processing. As I have seen, preparing these forms properly is a skillful technology to ensure that the material is uniformly dispersed in the base system.

How Different Forms of Cesium Tungstate Unlock Diverse Applications?

Cesium tungstate is a very powerful material for blocking infrared light. But its raw powder form is not always easy to use directly in production. To make it widely applicable, manufacturers process it into different forms. Each form helps to integrate the IR-blocking properties into specific products and manufacturing processes more easily.

Powder Form: This is the most basic form of cesium tungstate. It is a very fine powder.

- Advantages: It offers flexibility for formulators who want to create their own custom dispersions or compounds. This allows for precise control over the concentration of cesium tungstate.

- Disadvantages: Working with powders requires specialized equipment for dispersion to prevent agglomeration (clumping) and ensure uniform distribution in the final product. Improper dispersion can reduce the effectiveness of the material.

- Applications: Used by companies that have their own dispersion technology for making liquid coatings, inks, or masterbatches. It acts as the raw ingredient for other forms.

Liquid Dispersion Form: This is the cesium tungstate powder already dispersed in a liquid carrier. The carrier can be water, solvents, or resins.

- Advantages: Much easier to use than powder. The nanoparticles are already well-separated and stable in the liquid. This reduces processing time and the need for high-shear mixing by the end-user. It ensures better transparency and IR-blocking performance.

- Disadvantages: The carrier liquid must be compatible with the user's application. The concentration of cesium tungstate is fixed in the dispersion.

- Applications: Widely used in coatings for architectural glass, automotive films, plastic sheets, and textiles. It is also used in transparent heat-insulating films.

Masterbatch Form: This involves mixing a high concentration of cesium tungstate powder into a polymer resin. This creates small pellets or granules.

- Advantages: Extremely easy to use in plastic processing like injection molding, extrusion, or film blowing. Users simply mix the masterbatch with virgin polymer pellets in the desired ratio. This provides excellent dispersion and avoids handling fine powder. It prevents dust and ensures safety.

- Disadvantages: Less flexible in terms of concentration. The chosen polymer carrier must be compatible with the final product's base polymer.

- Applications: Ideal for manufacturing IR-blocking plastic components, such as polycarbonate sheets for greenhouses, PMMA panels, PET films for agricultural use, or other transparent plastic parts needing heat insulation.

The "skillful technology" I mentioned earlier comes into play here. It's all about how well these tiny particles of cesium tungstate are spread out in the liquid or polymer. If they clump together, they won't block IR effectively. Our team at Langyi spends a lot of time perfecting these dispersion methods to make sure our clients get the best performance from our additives.

Conclusion

Cesium tungstate stands out as a powerful infrared-blocking material. Its ability to absorb and scatter IR radiation makes it vital for thermal management. Available in powder, liquid, and masterbatch forms, it offers flexible solutions across many industries.

Understand infrared radiation and its impact on materials and thermal management. ↩

Discover how thermal management applications utilize materials like cesium tungstate for better efficiency. ↩

Explore the technology behind smart windows and their use of infrared blocking materials. ↩

Explore the electromagnetic spectrum and where infrared radiation fits within it. ↩