Comparison of polycarbodiimide crosslinker and isocyanate crosslinker

Polycarbodiimide Crosslinker and Isocyanate Crosslinker are two different types of crosslinking agents used in various applications. Here are the key differences between them:

- Chemical Composition

Polycarbodiimide crosslinkers are derived from polycarbodiimide compounds, which are formed by the reaction of isocyanates with urea or other carbodiimide-forming agents. Isocyanate crosslinkers, on the other hand, are compounds containing one or more isocyanate functional groups, typically derived from diisocyanates. - Reaction Mechanism

Polycarbodiimide crosslinkers work through a non-isocyanate crosslinking mechanism. They react with carboxyl groups at elevated temperatures to form crosslinked networks. Isocyanate crosslinkers, on the other hand, react with hydroxyl groups to form urethane linkages, leading to crosslinking. - Crosslinking Properties

Polycarbodiimide crosslinkers offer delayed or slower crosslinking compared to isocyanate crosslinkers. This delayed reaction allows for extended working times and better flow and leveling properties during application. Isocyanate crosslinkers generally have faster crosslinking kinetics and can provide quick curing or drying of coatings or adhesives. - Stability and Yellowing

Polycarbodiimide crosslinkers have better stability against yellowing compared to isocyanate crosslinkers. They tend to offer improved color retention and resistance to discoloration, especially in light-colored or white coatings. - Safety and Environmental Considerations

Polycarbodiimide crosslinkers are considered safer and more environmentally friendly compared to isocyanate crosslinkers. Isocyanates are known to be potential respiratory and skin sensitizers, requiring strict handling precautions and proper ventilation during application.

Application areas of polycarbodiimide crosslinkers

Polycarbodiimide crosslinkers find applications in various industries and products where crosslinking is desired. Here are some common application areas of polycarbodiimide crosslinkers:

Coatings: Polycarbodiimide crosslinkers are widely used in the formulation of coatings, such as automotive coatings, industrial coatings, wood coatings, and protective coatings. They provide enhanced film integrity, adhesion, chemical resistance, and durability to the coatings. See more information about polycarbodiimide’s application on 3C electronic coatings.

Adhesives: Polycarbodiimide crosslinkers are employed in the formulation of adhesives, including structural adhesives, laminating adhesives, and sealants. They improve the bonding strength, heat resistance, and mechanical properties of the adhesives.

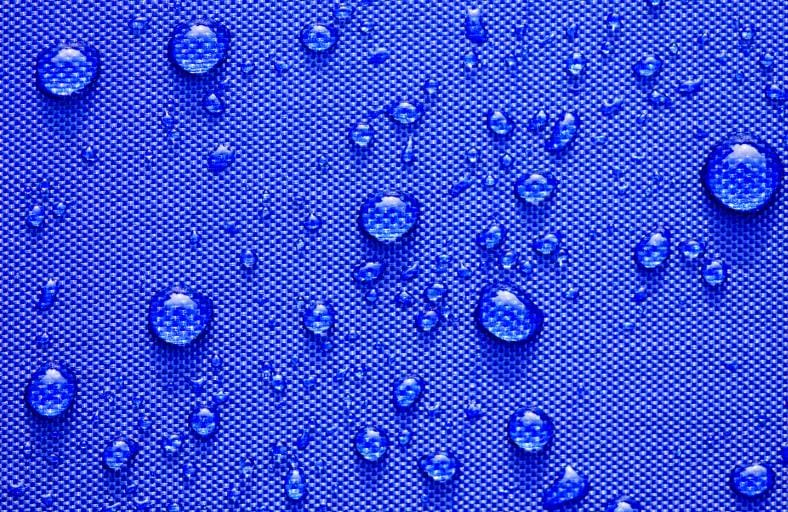

Textiles: Polycarbodiimide crosslinkers are used in the textile industry for the crosslinking of fibers and fabrics. They enhance the dimensional stability, crease resistance, and durability of textile materials, making them suitable for applications such as apparel, home furnishings, and technical textiles. See more information about polycarbodiimide’s application on textile printing inks.

Automotive: Polycarbodiimide crosslinkers are utilized in automotive applications, including interior trims, foam molding, and seat cushioning. They provide improved heat resistance, dimensional stability, and mechanical strength to the automotive components.

Electronics: Polycarbodiimide crosslinkers find applications in the electronics industry for the encapsulation and protection of electronic components. They offer excellent moisture resistance, adhesion, and mechanical stability to ensure the longevity and reliability of electronic devices.

Packaging: Polycarbodiimide crosslinkers are used in packaging materials, such as films and coatings, to improve their barrier properties, heat resistance, and adhesion. This enhances the shelf life, protection, and overall performance of packaged products.

Langyi is a developing and manufacturing company specializing in polycarbodiimide crosslinkers. As a leading innovator in the field, Langyi is dedicated to creating cutting-edge solutions using polycarbodiimide to meet the diverse needs of its customers across various industries. If you are interested in the application of polycarbodiimide or need a sample for test, feel free to contact us.