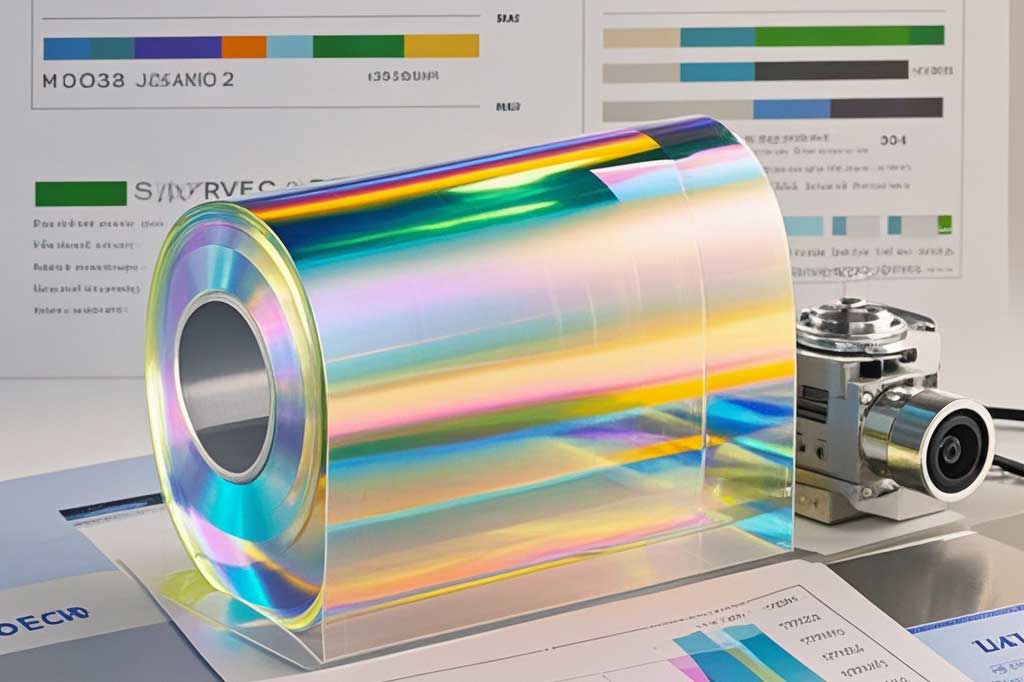

BOPET (biaxially oriented polyethylene terephthalate) films play an important role in multiple industries today, such as photovoltaics and electronics. Unfortunately, they also pose the threat of hydrolysis, which can negatively impact performance and lifespan – this is where anti-hydrolysis agents come into play.

The Significance of BOPET in Photovoltaics and Electronics

BOPET films play an indispensable role in photovoltaics and electronics industries. In photovoltaics, they serve as backsheets that protect cell modules from heat, humidity and UV rays; in electronics they’re used as displays such as LCD and OLED screens requiring excellent optical properties and stability; for electronic tags and packaging BOPET requires moisture resistance and anti-static properties – ultimately BOPET is key in providing products in these industries with reliable operation and longevity – guaranteeing performance and longevity in operation and durability over their lives.

The Problem of Hydrolysis in BOPET

Hydrolysis is caused by moisture present in high temperature and humidity environments. If hydrolysis does occur, it can result in reduced mechanical properties, optical performance degradation and service life reduction. For instance photovoltaic backsheet films may become brittle over time due to hydrolysis leading to reduced protection function for photovoltaic cell modules while electronic displays could have their brightness reduced as a result of hydrolysis.

See more about what is hydrolysis?

Anti-Hydrolysis Agents mechanism

Anti-hydrolysis agents work by reacting with the hydrolysis products produced from BOPET polymers. By binding to and reacting with them, anti-hydrolysis agents can capture any generated carboxyl groups, and stop further hydrolysis reactions thereby strengthening and stabilizing polymers while increasing resistance against hydrolysis reactions. This approach increases stability of polymer chains while increasing resistance against hydrolysis reactions.

Anti-Hydrolysis Agents in BOPET

There are multiple approaches for adding anti-hydrolysis agents to BOPET. Different anti-hydrolysis agents offer distinct characteristics and should be chosen based on application needs. One popular strategy involves blend addition during production process while surface treatment may improve anti-hydrolysis performance of film on surface.

Impact of Anti-Hydrolysis Agents on BOPET Performance

Anti-hydrolysis agents can have a dramatic impact on BOPET films’ performance, both mechanically and weather resistantly. Mechanically, anti-hydrolysis agents increase tensile strength while maintaining elongation at break. Weather resistance becomes enhanced in high temperature/high humidity environments.

Application Cases

In the photovoltaic field, adding anti-hydrolysis agents to BOPET films used as photovoltaic backsheets can significantly extend their service life and ensure long-term stability and reliability of photovoltaic cells modules. Anti-hydrolysis agents also protect OLED displays by protecting BOPET packaging material against hydrolysis.

Evaluation of BOPET Film by PCT Aging Test

The Pressure Cooker Test (PCT) Aging Test for BOPET film is an integral evaluation method. In this procedure, BOPET film is exposed to high temperature and pressure environments within a pressure cooker or special testing chamber in order to simulate real world conditions as encountered by its lifespan, such as increased humidity or heat exposure.

Test duration should be carefully determined to speed up the aging process and monitor any changes in film properties such as mechanical strength, optical clarity and dimensional stability. Any indications of degradation such as loss of strength or increased haze could point to potential issues for real world applications.

This test is essential to the production of BOPET film. Manufacturers can use its results to enhance manufacturing processes and select appropriate materials to ensure durability and reliability of their film products. Furthermore, this testing helps manufacturers meet industry standards as well as customer expectations of high-performance BOPET films.

Conclusion

Anti-hydrolysis agents are indispensable in improving the performance and lifespan of BOPET films used for photovoltaic applications in photovoltaic cells and electronics products. With new technological developments emerging every day, anti-hydrolysis agents’ role is likely to grow increasingly important when it comes to safeguarding quality and reliability of these essential materials.