As climate change and energy demand exacerbate one another, finding sustainable and renewable sources has never been more crucial. Photovoltaic (PV) technology – which converts sunlight directly to electricity – has emerged as one such renewable solution, making PV modules key factors when considering solar energy use in terms of effectiveness and economic viability.

Conceptual Framework of Photovoltaic Cell

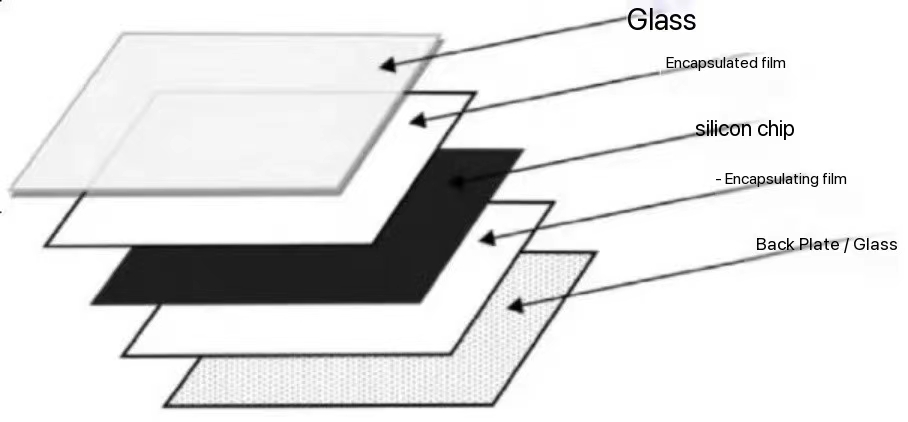

A photovoltaic module typically comprises several essential components. Tempered glass provides protection from the elements while still allowing sunlight through, while solar cells transform sunlight into electrical energy. An encapsulant, usually an EVA (Ethylene Vinyl Acetate) film, plays an essential role in bonding the various components together and protecting delicate solar cells, with backsheet insulation providing additional insulation and protection from outside forces.

Composition of crystalline silicon photovoltaic modules

EVA Film’s Importance in PV Modules

The EVA film is not just a simple component; it serves as a crucial interface within the PV module. It not only ensures the mechanical integrity of the module by holding the different parts together but also acts as a barrier against moisture, oxygen, and other environmental factors that could potentially damage the solar cells. However, standard EVA films have their limitations. When exposed to extreme conditions such as high voltage, elevated temperatures, and high humidity, they may give rise to a phenomenon known as Potential Induced Degradation (PID).

Understanding Potential Induced Degradation (PID)

PID is a phenomenon that occurs when an electrical potential difference, combined with harsh environmental conditions such as high voltage, high temperature, and high humidity, leads to electrochemical reactions within the PV module.

The Causes of the PID Effect

The causes of the PID effect are rather complex and mainly include the following aspects: The grounding installation method of the module frame of the photovoltaic power station creates a high potential between the solar cell and the ground; external conditions such as temperature, humidity, voltage, light, and the grounding conditions of the glass surface; in the practical application of components such as glass, encapsulation film, solar cells, and backsheets contained in the photovoltaic module, it causes different degrees of Na+ movement.

Crystalline silicon cells mainly come in two types: n-type and p-type. In n-type cells, doping the silicon wafer with phosphorus makes the cell negatively charged. The cause of the PID effect is the surface polarization of the antireflection film; in p-type cells, doping the silicon wafer with boron makes the cell positively charged. The cause of the PID effect is the drift and diffusion of Na+.

The Existing Solutions for the PID Effect

Limited by the usage scenarios and existing installation technologies, the improvement of the anti-PID performance of existing components is mainly based on the photovoltaic components themselves. The PID effect of n-type crystalline silicon solar cells can improve the anti-PID performance by using a passivation layer to reduce the dielectric constant and increase the conductivity.

The PID effect of p-type crystalline silicon solar cells can improve the anti-PID performance of the components by reducing the Na+ migration rate. The currently reported modification studies are mainly carried out at the component, module, and system levels.

- Component level: The anti-PID performance of solar components can be improved by changing the resistivity of the silicon wafer, the N/Si ratio, the thickness and uniformity of the antireflection layer on the surface of the solar cell.

- Module level: By adding an anti-PID coating to the glass surface; optimizing the content of vinyl acetate (VA) in the ethylene-vinyl acetate copolymer (EVA) and the ratio of various additives such as anti-PID powder to increase the volume resistivity of the encapsulation film; using encapsulation materials with higher volume resistivity (such as polyolefin, etc.).

- System level: With the continuous expansion of the scale of photovoltaic power stations, it is necessary to increase the number of series-connected solar components and reduce the use of inverters. Choosing a suitable grounding electrode in the solar power generation system is also one of the possible solutions for PID. For p-type crystalline silicon photovoltaic components, preventing the drift and diffusion of Na+ is the starting point for improving the anti-PID performance of the components.

Anti-PID EVA Masterbatch

Anti-PID EVA masterbatch has been developed as an innovative material designed to address PID. This cutting-edge material features additives and modifiers specifically tailored for decreasing PID risks while improving electrical insulation properties and resistance to electrochemical degradation. As a result, resilient environmental conditions significantly lower PID risks while guaranteeing long-term module stability and performance.

Process of Implementing Anti-PID EVA Masterbatch

An EVA masterbatch designed to reduce PID is added with careful and controlled steps. A precise proportion, typically between 1-2% of masterbatch is mixed into the base EVA material prior to extrusion for optimal anti-PID performance and to meet specific module requirements and manufacturing processes. Thorough and uniform mixing between masterbatch and EVA material must occur for maximum consistency in its anti-PID properties within each film created from it.

Benefits of Anti-PID EVA Masterbatch

Anti-PID EVA masterbatch offers numerous advantages. PV modules containing this masterbatch have demonstrated remarkable reductions in power degradation over time, even under harsh operating conditions, leading to more consistent and efficient energy production over the lifespan of their modules, producing higher returns on investment for solar power projects. Furthermore, its addition contributes to enhanced mechanical strength and durability of EVA films, increasing resistance against cracking or delamination which improves overall reliability and lifespan of PV modules.

Conclusion

In conclusion, Anti-PID EVA masterbatch represents an exciting development in photovoltaic module manufacturing. With its ability to increase performance, durability and reliability of PV modules it makes for an indispensable element in our pursuit of sustainable energy use and more efficient solar energy exploitation. As we strive toward cleaner energy solutions the Anti-PID EVA masterbatch will play an integral part in shaping its landscape in terms of shaping our energy future.