Introduction to PET:

Polyethylene Terephthalate (PET) is a widely used plastic material found in bottles, containers, and packaging. Its excellent physical properties and chemical stability make it an important material in industries. PET is extensively used in the production of industrial monofilaments and paper machine clothing area due to its high strength and durability.

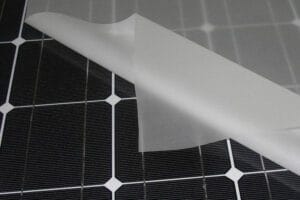

Application of PET in Industrial Monofilaments and paper machine clothing:

Industrial monofilament manufacturing often requires materials with high strength and resistance to wear. PET’s exceptional mechanical properties make it an ideal choice for producing industrial monofilaments used in ropes, fibers, meshes, and more, exhibiting outstanding mechanical performance and tensile strength in these applications. The use of PET fibers in paper machine clothing is also crucial. These fabrics typically demand excellent durability, tensile strength, and resistance to corrosion, all of which PET fibers provide. As a result, these fabrics find wide application in various types of paper machine clothing production.

However, a notable challenge lies in the susceptibility of these monofilaments to breakage and damage, resulting in increased downtime and frequent replacements within paper machine clothing. These issues predominantly arise from the hydrolysis of PET materials induced by high temperatures and humidity, compounded by tension and wear, especially in demanding operational conditions

Hydrolysis of PET and its mechanism:

The hydrolysis of PET (Polyethylene Terephthalate) involves the breakdown of its chemical structure due to exposure to water and certain conditions. This process primarily targets the ester linkages within the PET polymer chains. The mechanism of hydrolysis typically involves the action of water molecules in the presence of specific catalysts or conditions, such as high temperature or acidic environments.

Click to see what is hydrolysis

The ester bonds in PET molecules are susceptible to hydrolysis. Water molecules can attack these bonds, causing them to break. This reaction results in the splitting of the PET polymer chain into smaller fragments. Specifically, the ester linkage (-CO-O-) in PET is vulnerable to nucleophilic attack by water molecules. This attack leads to the cleavage of the ester bond, resulting in the formation of two products: terephthalic acid and ethylene glycol.

Acid Hydrolysis of PET

In acidic hydrolysis, the presence of an acid catalyst facilitates the breakdown of PET. For instance, sulfuric acid can protonate the ester linkage, making it more reactive and prone to hydrolysis by water molecules. This process accelerates the cleavage of the ester bond, leading to the production of terephthalic acid and ethylene glycol.

Application of anti-hydrolysis agent in PET

Anti-hydrolysis agents play a critical role in PET (Polyethylene Terephthalate) applications by enhancing its resistance to degradation caused by hydrolysis. These agents are incorporated into PET formulations to mitigate the effects of water exposure, particularly in environments where PET is susceptible to hydrolytic degradation. By adding anti-hydrolysis agents, the material’s stability and durability are significantly improved, prolonging its lifespan and retaining its mechanical and chemical properties even in conditions prone to hydrolysis. This application of anti-hydrolysis agents in PET is pivotal, especially in industries reliant on PET-based products where preserving material integrity is essential for extended usability and reduced environmental impact.

What is PET masterbatch?

PET masterbatch refers to a concentrated form of additives, often in powdered form, designed to enhance PET (Polyethylene Terephthalate) properties, particularly its resistance to hydrolysis. These anti-hydrolysis agent additives are incorporated into a PET resin carrier to create anti-hydrolysis masterbatch pellets. These masterbatch pellets are easily added to the base PET material during processing. By using anti-hydrolysis masterbatch, manufacturers can effectively and conveniently improve the PET’s durability against water-induced degradation, simplifying the production process and ensuring consistent distribution of anti-hydrolysis agents within the PET material.