Introduction of PLA/PBAT

As environmental awareness has increased in recent years, so have degradable materials like PLA (polylactic acid) and PBAT (poly(butylene adipate-co-terephthalate) come under scrutiny. PLA is a biodegradable thermoplastic polyester with excellent biocompatibility and mechanical properties made of renewable biomass resources such as corn starch; on the other hand, PBAT offers flexible processing properties and processing versatility; when combined, their combination has given rise to new opportunities in materials science.

PLA/PBAT materials have shown tremendous promise across various fields. Their applications span the packaging industry (food packaging and shopping bags); agriculture (making agricultural mulch films less polluting); disposable products like tableware and straws; all these applications not only meet people’s daily needs but also support sustainable development concepts.

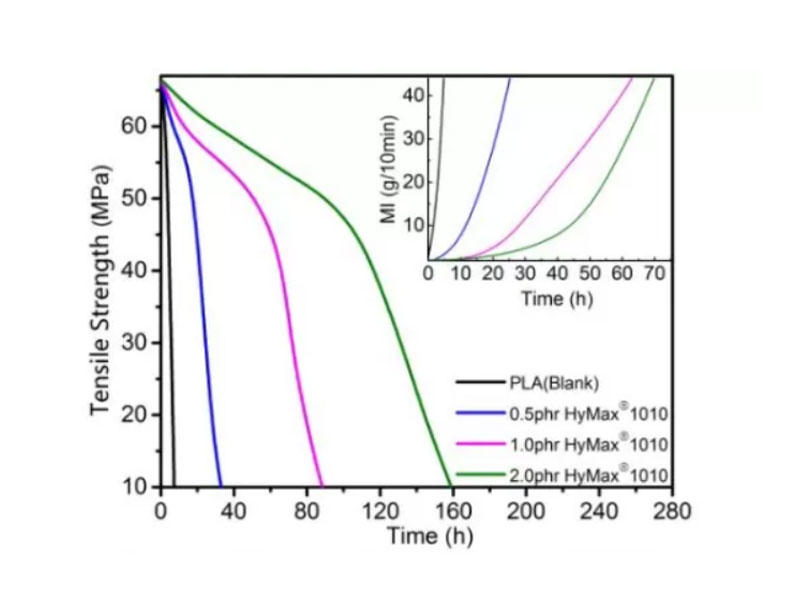

PLA/PBAT materials encounter serious challenges when exposed to environments with both high temperature and humidity levels. High temperature can accelerate molecular motion while high humidity provides water molecules needed for hydrolysis reactions that lead to polymer chain breakage resulting in decreased tensile strength, poor toughness, sticky surfaces or deformation – creating risks to consumer health as a whole.

Applications of PLA/PBAT

Here are key applications of PLA/PBAT blends, particularly in industries focused on sustainability:

1. Food Packaging

Compostable Packaging Films: PLA/PBAT blends are commonly used to make flexible, biodegradable films for food packaging, such as bags, pouches, and wraps. These films maintain good barrier properties, keeping food fresh while also being compostable.

Biodegradable Food Containers: Rigid PLA/PBAT blends are molded into trays, clamshells, and other single-use containers for foods. They offer a sustainable alternative to traditional plastic packaging with comparable performance.

Disposable Utensils and Tableware: PLA/PBAT is often used to produce forks, knives, spoons, and plates for single-use applications, especially in settings prioritizing compostable materials.

2. Agricultural Films and Mulch

Compostable Mulch Films: PLA/PBAT blends are used to create films that cover soil to retain moisture, control weeds, and improve crop yield. At the end of the growing season, these films biodegrade, eliminating the need for removal and disposal.

Seedling Pots and Trays: PLA/PBAT is used in seedling trays and pots that can be planted directly in soil. These products gradually decompose, minimizing waste and soil disruption.

3. Compostable Bags

Shopping and Garbage Bags: PLA/PBAT blends are popular for making compostable bags for shopping, trash, and organic waste disposal. These bags are designed to break down in industrial composting facilities, supporting waste management efforts.

Pet Waste Bags: Used for collecting pet waste, these compostable bags are an eco-friendly alternative to standard plastic bags, reducing plastic pollution.

Working Principle of Anti-hydrolysis Agents in High Temperature and Humidity Environments

- Neutralizing Acids and Catalysts

PLA and PBAT may deteriorate through hydrolysis, in which water molecules break down polymer chains to result in weaker mechanical strength, increased brittleness and decreased lifespan – often hastened by acidic catalysts. To address this situation, neutralization techniques must be implemented quickly in order to mitigate acidity from acid catalysts that speed this degradation process up further.

Anti-hydrolysis agents act to neutralize acidic or catalytic sites within polymer matrix to limit protons (H+ ions) formation that could accelerate hydrolysis reactions.

- Scavenging Moisture

In high humidity environments, anti-hydrolysis agents can act as desiccants by absorbing or chemically binding with free water molecules within polymer structures to decrease hydrolysis rates. By decreasing free water molecules within polymers and thus hydrolysis processes.

Certain carbodiimide-based agents react with water to form stable by-products that reduce free water concentration, thus slowing hydrolytic degradation.

- Repair the Broken Polymer Chains

Anti-hydrolysis agents such as polycarbodiimide may facilitate limited cross-linking within polymer chains to create more stable networks that are less vulnerable to breakdown, thus decreasing chain scission due to hydrolysis. Cross-linking also strengthens mechanical integrity under stress, making the polymer less vulnerable to embrittlement and degradation under extreme environmental conditions.

- Thermal Stabilization

Since hydrolysis can often be accelerated by heat, some anti-hydrolysis agents provide thermal stabilization by maintaining molecular structures at higher temperatures. This prevents thermal breakdown which could otherwise increase water molecules’ interactions with each other and with polymers.

Introduction of food contact safe anti–hydrolysis agent

Food contact safe anti-hydrolysis agent must meet stringent food safety standards in order to be suitable for contact with food. Such an agent must typically be nontoxic, odorless and do not introduce harmful substances into food through migration. HyMax 210 has proven a safe food contact anti-hydrolysis agent with the testing base on both US and Chinese food contact standard.

Application effect of food contact safe anti-hydrolysis agent in PLA/PBAT

Anti-hydrolysis agents have proven their value in improving PLA/PBAT products under high temperature and humidity conditions, leading to significant enhancements of performance and stability in these applications. Experimental data indicates that the retention rate of mechanical properties for PLA/PBAT food packaging materials with anti-hydrolysis agents added significantly increases during high temperature steaming or exposure to humid and high-temperature environments for extended periods. Decreases in tensile strength and elongation at break can be effectively managed, and barrier properties of food packaging become more stable – providing greater freshness and quality preservation of food products. Furthermore, food grade hydrolysis stabilizer undergoes strict food contact safety tests so consumers can use food packaging containing such additives with confidence.

Conclusion

Food-contact Anti-hydrolysis agents play an integral role in PLA/PBAT products used in high – temperature, high – humidity environments. Not only do they effectively solve the hydrolysis issue in harsh conditions and ensure performance of materials; but they also safeguard food packaging safety. As environmental protection and food safety requirements increase, further research and optimization of such Anti-hydrolysis agents will provide greater assurances regarding wider application of PLA/PBAT materials within food packaging applications and further help the degradable materials industry develop in an eco-friendly and sustainable direction.