Polylatic acid, or PLA, is also referred to as polypropylene. PLA is a thermoplastic polymer obtained by polymerizing lactic acid as a main raw material. It has good biocompatibility, which can be completely degraded by natural microorganisms, and is an ideal green molecular material.

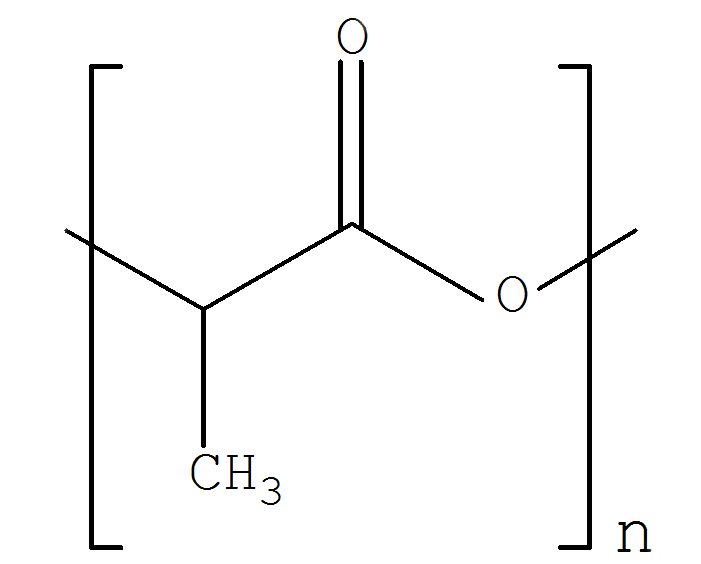

Polylactic acid molecular structure

PLA is a polymer material having good biocompatibility, high biological decomposition absorption, high strength, non-contaminated environment, plastic processed molding. It has good mechanical properties, high resistance strength, high flexibility and thermal stability, no variability, good transmigration, good transparency and with antibacterial, anti-mildew properties. Its service life can be 2 ~ 3 years.

With good machining performance, PLA is possible to qualify for the use of most synthetic plastics. It can be used to make packaging materials, home appliance housings, or as degradable fibrous materials. PLA is unanimously recognized as the most promising new “ecological materials” in the new century due to its renewable biological resources. PLA is a true biological plastic, which can thoroughly degrade into CO2 and H2O under the action of microorganisms in 30 days.

Application field of polylactic acid:

1) Biomedical field: polylactic acid has good biocompatibility, and has been widely researched and applied in the fields of osteogeneous surgery, thoracic surgery, maxillofacial surgery, tumor targeted treatment, such as housing surgery lines. , Vascular brackets, etc.

2) Food packaging materials: polylactic acid packaging materials have good biodegradability and antibacterial properties compared to materials such as polyethylene, polyvinyl chloride, polypropropylelend.

3) Industrial manufacturing areas: with its plasticity, heat resistance and physical processing performance, PLA can be processed as accessories engineering materials for automotive industries, construction ropes, etc.. It can also be served as a 3D printing wire to meet individual chemical industry customizes .

4) Agricultural production area: with its polylactic plasticity, heat resistance, biocompatibility, PLA can be processed as agricultural fiber membranes. It is used to make up for the traditional germ fragile and undesirable defects. It can be also processed into pesticide fertilizer sustained release materials, which will not cause ecology destroy.

Disadvantages of polylactic acid:

The polylactic acid can be completely degraded by microbes in the natural world, and ultimately produce carbon dioxide and water, and is friendly environment. Studies have shown that polylactic acid waste products are thoroughly degraded under the action of microorganisms, water, acid and alkali in the soil or water.

However, in the actual application, the rate of degradation of polylactic acid has become the focus of attention, and the excessive degradation rate will affect the application of polylactic acid. If the polylactic acid products are still in the shelf life, the decline or loss of the comprehensive performance caused by degradation, will influence its further promotion and application. Especially under some high temperature and high humidity conditions, polylactic acid will accelerate degradation, seriously affect the performance and service life of the products.

Therefore, how to achieve the control and regulation of the degradation rate of polylactic acid will become one of the key factors affecting its application and development.

Polylactic acid hydrolysis / water solution solution:

At present, the polylactic acid reduction rate can be controlled by controlling the purity of raw materials, and the addition of the aid, such as a hydrolysis agent, a crosslinking agent in the synthesis process. The most convenient way is to use the adding aid.

High Energy Hydrolysis Stabilizer HyMax® 1010

We have found that the conventional PLA spline is completely loses mechanical properties after cooked in 95℃ water for 8 hours. If 1.0% hydrolysis agent HyMax® 1010 is added to the PLA spline, after being cooked in 95℃ water for 8 hours, the tensile strength retention ratio of PLA was 91%.The tensile strength was maintained at 12 MPa after cooked in 95℃ water for 30 hours .

From this, the addition effect of the hydrolysis additive Hymax®1010 can be seen, and the degradation of the PLA can be effectively delayed.

The HyMax® 1010 is a new type, durable, high-energy carbodoxide hydrolysis stabilizer. It can effectively capture the end carboxyl group of the PLA molecule to produce a urea-based compound which has non-toxic side effects. Thus effectively prevents the PLA molecule from being degraded due to rapid degradation. In addition, the adjustment of the amount of the HyMax® 1010 can achieve the purpose of the regulation of the PLA degradation rate.