What is TPU

TPU is short for thermoplastic polyurethane elastomer rubber. Compared with traditional plastics, rubbers, and even metals, TPU has many performance advantages such as good low-temperature flexibility, high strength, good oil and acid resistance, environmental protection, and easy processing.

With economic development and consumption upgrades, the amount of TPU is increasing year by year. It has a wide range of applications in the automotive, clothing, shoe materials, outdoor sports, medical, electronics, industrial and other industries, such as TPU medical supplies, TPU automotive pneumatic tubes, TPU headphones and smart speakers.

Classification of TPU

TPU has many classification standards, the most common is divided into polyester type, polyether type and butadiene type according to the soft segment structure, which contains ester groups, ether groups, and butenyl groups respectively.

The difference between polyether and polyester TPU

1) The advantages of polyether and polyester TPU

Polyether type (Ether): high strength, hydrolysis resistance and high resilience, good low-temperature resistance performance.

Polyester type (Ester): better tensile properties, flexural properties, abrasion resistance, solvent resistance and higher temperature resistance.

2) Performance comparison between polyether type and polyester type TPU

Tensile strength, tear strength, abrasion resistance, chemical resistance, transparency: polyester series> polyether series

Bacterial resistance, low-temperature resistance: polyester series <polyether series

Oil resistance and anti-hydrolysis performance:

TPU has better oil resistance, but the anti-hydrolysis performance varies depending on the structure. The hydrolysis resistance of polyether polyurethane is 3 to 5 times that of polyester polyurethane because the ether group does not react with water.

There are two reasons for the deterioration of polyurethane performance caused by the intrusion of water: one is that the invading water forms hydrogen bonds with the polar groups in the polyurethane, which weakens the hydrogen bonds between polymer molecules. This process is reversible. The physical properties were restored later.

The second is that the invading water causes the polyurethane to be hydrolyzed, and this process is irreversible.

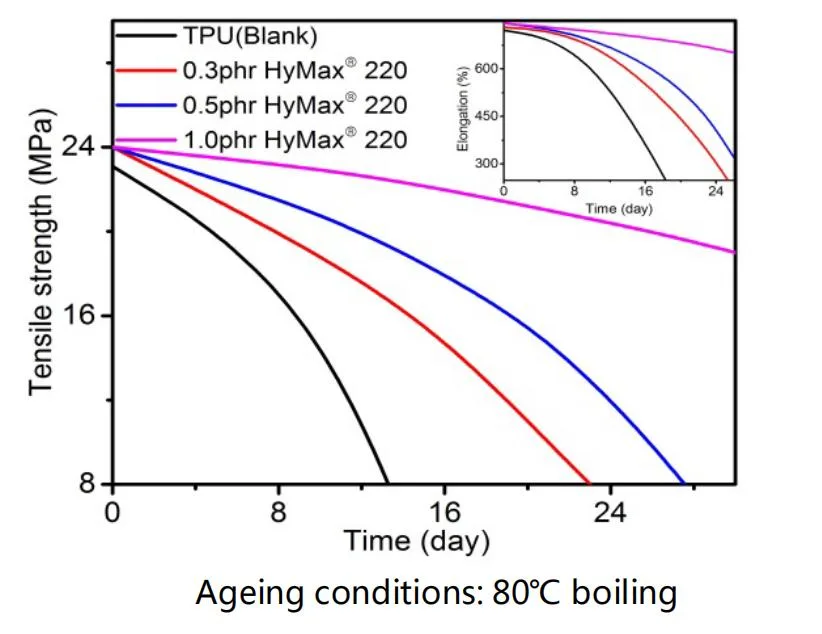

The hydrolysis of polyester TPU can be improved by adding an anti-hydrolysis agent. The addition of HyMax® 1010 anti-hydrolysis agent can significantly improve the tensile strength of TPU.

Polyurethane will change color and darken under long-term sunlight, and its physical properties will gradually decrease. Mold can also cause the degradation of polyurethane. Therefore, the polyurethane rubber used in industrial production is added with anti-aging agents, ultraviolet absorbers, and anti-mold agents.

Service Case of TPU hydrolysis

A TPU product produced by a customer needs to be exported to the United States. After shipping to the United States in the summer, it was found that the physical properties of the product could not meet the customer’s needs, but the domestic inspection far exceeded the customer’s requirements. Later, the highest temperature during the shipping process was 65°C and the humidity was 90%. After the shipping time was 25 days, the material was hydrolyzed, and then 0.5phr HyMax® 1010 was added to successfully solve this problem.

HyMax®1010 can be widely used in PU products, such as TPU, CPU, adhesives, coatings, shoe soles, microporous elastomers, etc. The general addition amount is 0.5-2.0 phr.

HyMax®1010 is usually added to polyester polyols or hydroxyl-terminated prepolymers. Adding 1 phr can increase the hydrolysis resistance of TPU by more than 3 times.

During use, it is recommended to melt HyMax® 1010 at 50°C-120°C, then add and stir. It is recommended to stir for at least 30 minutes at 120°C, which can greatly reduce the acid value of the polyester polyol.