Globally, the push for sustainability has led to a boom in recycled materials being used across all industries. Recycled polyethylene terephthalate has been gaining attention in many industries, especially the food packaging industry. Many companies are looking at rPET to replace virgin PET due to the growing concern about plastic waste. But the question is: Can rPET be used for food-grade packaging. This article explores the benefits, challenges, safety and regulatory standards of using rPET for food packaging. It also examines the benefits of using chain extenders to ensure its quality.

Understanding rPET Production Process

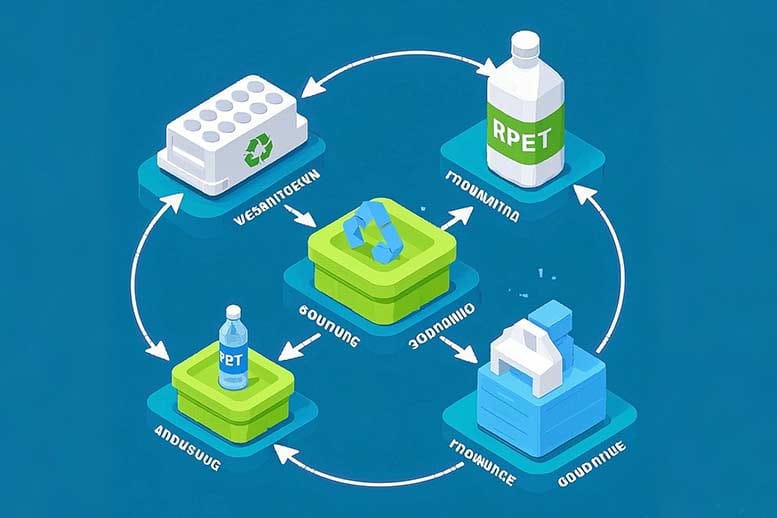

rPET can be made from PET bottles that have been used after they were purchased. This involves a collection, sorting and cleaning process, followed by reprocessing. Recycling methods are generally divided into two main categories:

- Mechanical Recyclage: PET flakes are ground and melted into new packaging.

- Recycling of Chemicals: The PET monomers are broken down and repolymerized to produce new PET with a higher purity.

Both methods are designed to reduce the environmental impact of PET, while maintaining its integrity. Nevertheless, ensuring safety and performance for rPET in food contact applications is a challenge.

Regulatory Standards For Food-Grade rPET

To be considered food-grade rPET, it must adhere to strict regulations established by international health authorities. Some of the key regulatory bodies are:

U.S. Food and Drug Administration (FDA): The FDA regulates rPET (recycled polyethylene terephthalate) for food-contact applications through guidelines including 21 CFR § 177.1630 (specific to PET) and its Guidance for Industry: Use of Recycled Plastics in Food Packaging. These documents outline testing protocols and safety thresholds to ensure contaminants are effectively removed during recycling processes.

European Food Safety Authority (EFSA): EFSA certifies recycling technologies under EU Regulation 10/2011 (general safety standards for food-contact plastics) and EC No 282/2008 (specific to recycled plastics). Evaluations are supported by scientific opinions (e.g., EFSA-Q-2020-00123), which validate the efficacy of decontamination processes and compliance with migration limits.

China National Food Safety Standards: Key standards such as GB 4806.1-2016 (general safety requirements) and GB 31604.1-2015 (testing methods) define permissible contaminant levels, processing criteria, and migration thresholds for recycled plastics like rPET in food-contact materials.

The regulatory approval process is based upon a combination scientific assessments, migration tests, and validations of the recycling processes to ensure no harmful substances are migrating into food.

Challenges of using rPET in food packaging

While rPET is an environmentally friendly material, it does have some challenges.

- Contaminants Post-consumer plastics can contain chemicals, inks and adhesives which may compromise the food safety.

- Polymer Chains Degradation: The process of recycling, particularly mechanical recycling, may cause polymer chains degradation, reducing the material’s performance.

- Color Issues: The color and clarity of rPET may vary from virgin PET. This can affect the consumer’s perception.

- Cost considerations: Food-grade rPET requires extra processing and therefore costs more than virgin PET.

The role of chain extenders in enhancing rPET applications for food contact

Chain extenders are one of the best ways to improve the properties of rPET. These additives are crucial in restoring rPET’s molecular weight, mechanical properties and making it suitable for high performance applications.

- Enhancing Molecular Weight: The chain extenders rebuild broken polymer chains to increase strength.

- Improving Processingability: PET recycled is often thinner and harder to process. Chain extenders restore viscosity and ensure smoother production.

- Reducing yellowing and Enhancing Clarity Some advanced chain extenders improve the color and clarity of rPET to make it more visually attractive for food packaging.

- Boosting thermal stability: Packaging for food is often exposed to high temperatures. Chain extenders increase the thermal stability of rPET and ensure that it can withstand processing conditions.

The Benefits of using rPET for Food Packaging

Despite its challenges, rPET has several advantages which make it a viable choice for sustainable packaging of food:

- Reducing the Environmental Impact : Using rPET helps reduce carbon emissions, and conserves resources.

- Circular Economic Support rPET is a material that contributes to the closed-loop system of recycling, which promotes a more sustainable packaging sector.

- Consumer appeal: As consumers become more environmentally conscious, they are more inclined to support brands that use recycled packaging.

- Regulatory Sustainability and Corporate Goals Many global brands set ambitious targets for increasing recycled content in packaging. rPET is a key component of sustainability strategies.

Future Outlook of rPET Food Packaging

As technology improves, rPET will play a greater role in packaging food. Watch out for:

- Advanced Recycling Technologies: Improved decontamination and sorting methods will improve rPET purity.

- Innovative additives: The next-generation chain extenders will improve the performance of rPET.

- Stricter Regulations: Governments, organizations and businesses are likely to place stricter regulations and industry standards on recycled materials. This will encourage innovation and higher standard.

- Brand Commitments and Consumer Demand As sustainability is a major factor in purchasing, brands will increase the rPET content of their packaging.

Conclusion

rPET is a promising material for food packaging. However, its implementation will require careful considerations of safety, performance and regulatory compliance. rPET is able to meet the strict requirements of food-grade applications by leveraging innovative additives such as chain extenders and advanced recycling technologies.

Chain extenders are a great solution for manufacturers who want to improve the mechanical properties, processingability and overall quality of their rPET formulations. Continuous innovation will be crucial as the industry develops to make rPET a popular choice for food packaging. This will support both environmental sustainability and consumers’ expectations.

Visit [your company’s website] to learn more about our high-performance chain extensors for rPET and how we can enhance your sustainable packaging.