What is PU?

Polyurethane (PU) is a polymer material whose molecules contain repeating units of ether or ester bonds. PU has a wide range of excellent properties, including abrasion resistance, oil resistance, solvent resistance, and good elasticity, so it is widely used in many fields, such as synthetic leather, coatings, adhesives, sealants, and foams.

Classification of Polyurethane

Polyurethane (PU) can usually be categorized into two types according to its main raw material type and chemical structure:

Polyester-based Polyurethane: Polyester-based PU is a polymer made by reacting polyester polyols with isocyanates (or isocyanate blends). This type of PU has high heat resistance and solvent resistance, and is commonly used in the preparation of coatings, adhesives, elastomers, synthetic leather and so on.

Polyether-based Polyurethane: Polyether-based PU is a polymer made by reacting a polyether polyol with an isocyanate (or isocyanate blend). Compared to polyester-based, polyether-based PU has better low-temperature resistance and water resistance, so it has a wider range of applications in some specific areas, such as elastomers and foams.

Manufacturing process of polyurethane PU leather

The manufacturing process of polyurethane leather involves the application of polyurethane to a substrate, which is then processed and treated to obtain the desired appearance and properties. The main steps include:

Substrate selection: The substrate is usually a textile such as polyester or cotton. Selecting the right substrate is critical to the quality of the final product.

Coating: A polyurethane resin is applied to the substrate to form a coating. This step determines the texture and appearance of the PU leather.

Processing: The coating is processed and treated, often including embossing, dyeing and sanding, to give the PU leather the desired texture and color.

Curing: Finally, the coating needs to be cured to ensure its durability and stability.

How to keep PU leather from cracking?

Cracking is one of the common problems of PU leather, here are the ways to prevent cracking:

Use anti-hydrolysis agent during production: Adding anti-hydrolysis agent such as carbodiimide to PU manufacturing process can enhance the durability of PU leather and reduce the risk of cracking. This is only suitable for Polyester-based Polyurethane.

Avoid excessive stretching: Avoid applying excessive stretching force on the surface of PU leather, which may damage the integrity of the PU coating.

Keep it moist: Moderate humidity helps to maintain the softness and elasticity of PU leather, thus reducing the possibility of cracking. Moisturizers or conditioners can be used regularly to keep the surface of the leather moist.

How carbodiimide anti-hydrolysis agent is added to Polyester-based Polyurethane?

The use of carbodiimide anti-hydrolysis agents is an effective way to improve the hydrolysis resistance of PU during the polyurethane (PU) manufacturing process. There are two ways to use carbodiimide hydrolysis inhibitors: one is to incorporate them into the polyester polyol that is the raw material for PU, and the other is to add them directly to the PU resin.

First, it is a common practice to incorporate carbodiimide anti-hydrolysis agents into the polyester polyol that is the raw material for PU. By mixing the carbodiimide anti-hydrolysis agent with other raw materials at the polyester polyol stage of PU preparation, it can be ensured that it is uniformly dispersed throughout the PU material. This can effectively enhance the hydrolysis resistance of the PU and improve its stability in humid environments.

Another method is to directly add the carbodiimide anti-hydrolysis agent into the PU resin. During the preparation of the PU resin, the carbodiimide anti-hydrolysis agent can be mixed with the PU resin to ensure its full interaction with the resin. This method can directly improve the hydrolysis resistance of PU resin and make it more stable and reliable in use.

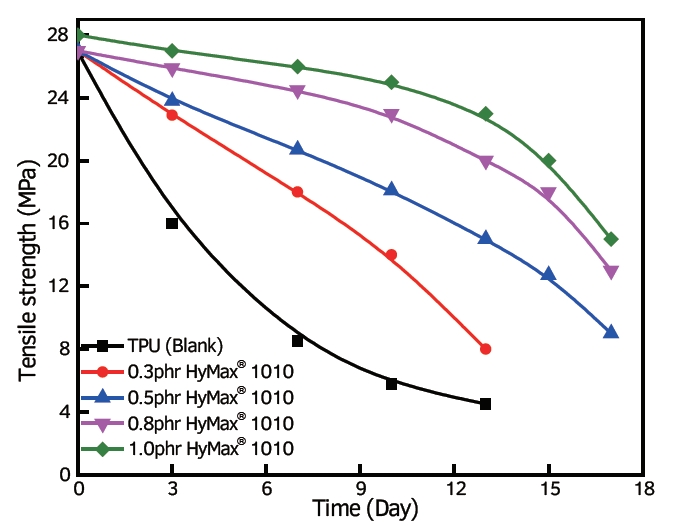

Application effect of carbodiimide anti-hydrolysis agent in Polyester-based Polyurethane: