HyMaxTM series of anti-hydrolysis agents can react with carboxylic acids produced by polymer decomposition to produce stable urea-based compounds with no side effects. It can slow down the process of polymer hydrolysis, prolong the service life of polymer, and solve the problem of comprehensive performance degradation caused by polyester material hydrolysis.

| Poduct Model | HyMax 1010 |

|---|---|

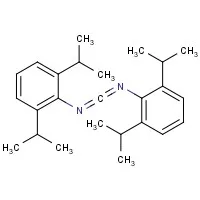

| Chemical Name | Bis(2,6-diisopropylphenyl)carbodiimide |

| Appearance | white or slightly yellow powder |

| Classifictaion | Monomer carbodiimide |

| Applied Materials | CPU, PBAT, PBT, PET, PLA, PU adhesive, TPEE, TPU |

| Feature | cost-effective, widely used |

| Product Name | HyMax 1010 anti-hydrolysis agent |

| Replacement Names | Stabaxol 1 Stabaxol I Hycasyl 1001 Additin RC 8500stabilizer 7000 Eustab HS-700Carbodiimide, bis(2,6-diisopropylphenyl)- (7CI,8CI) 2,2′,6,6′-Tetraisopropyl diphenyl carbodiimide N,N’-methanediylidenebis(2,6-diisopropylaniline) N,N’-(2,2′,6,6′-Tetraisopropyldiphenyl)carbodiimide N,N’-Bis(2,6-diisopropylphenyl)carbodiimide N,N’-Di-2,6-diisopropylphenylcarbodiimide |

| CAS Number | 2162-74-5 |

| Molecular Formula | C25H34N2 |

| Product Structure |  |

| Appearance | White to yellowish crystals |

| Category | Monomeric carbodiimide/ Biscarbodiimide |

| Applied Materials | PET、TPU、PLA、PU Adhesive, Polyester polyol |

| Feature | High cost performance and wide application |

HyMax can provide PET, TPU and other anti-hydrolytic masterbatches for direct injection or extrusion.

HyMax series of anti-hydrolysis agents can react with carboxylic acids produced by polymer decomposition to produce stable urea-based compounds with no side effects. It can slow down the process of polymer hydrolysis, prolong the service life of polymer, and solve the problem of comprehensive performance degradation caused by polyester material hydrolysis.

Ester-based polymer materials made of polyols and polyacids, such as PET, PBT, PU, PLA, PBAT, PC, etc.PET has good fiber forming property, mechanical property, abrasion resistance, creep resistance and electrical insulation; PU has high strength, abrasion resistance and oil resistance. PLA, PBAT are biodegradable green and environmental protection.

However, ester based polymer materials generally have a disadvantage, in the humid environment, especially at high temperature, the ester bond is prone to hydrolysis, thus reducing its comprehensive performance and service life. The hydrolysis of ester bond is the cause of the decrease of service life of ester-based polymer materials.

HyMaxTMseries of anti-hydrolysis agents can react with carboxylic acids produced by polymer decomposition to produce stable urea-based compounds with no side effects. It can slow down the process of polymer hydrolysis, prolong the service life of polymer, and solve the problem of comprehensive performance degradation caused by polyester material hydrolysis.

HyMaxTM is suitable for all polymers that contain ester bonds and the final product is used for long periods in wet and hot conditions, such as outdoors.

| Polymers | Application fields | ||||

| TPU | Shoe industry | Pneumatic pipe | Film | Conveyor belt | Elevator wheel |

| PU | PU adhesive | Ester flexible foam | Pouring type PU (cutting guide wheel) | PU leather | Spandex |

| PET | Industrial monofilament | Special polyester film | Engineering plastics | Fiber | Reusing plastic |

| PLA | Tableware | Engineering plastics | 3D printing wire | Agricultural plastic mulching film | Fiber |

| PC | Automobile lampshade | Automotive upholstery | Luggage rack of high-speed rail | Film | Overhead soundproof panel |

| PBT | Electric products | Film | Instrument panel | Foglight | Car grilles |

We will contact you within 1 working day, please pay attention to the email with the suffix “@langyitech.com”.