【general introduction】

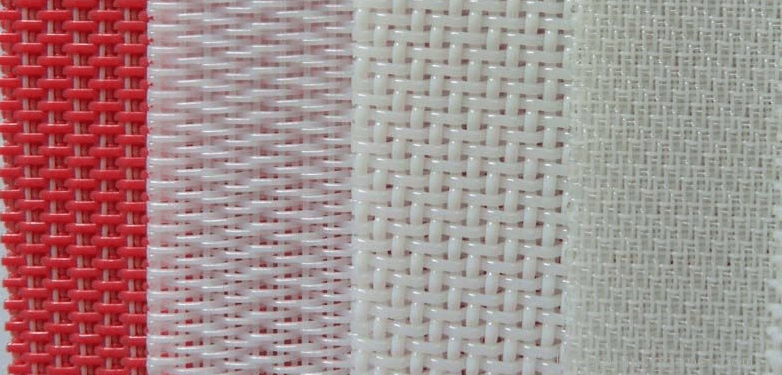

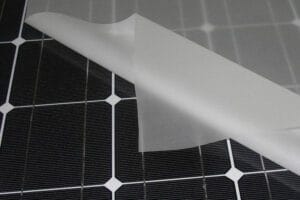

The drying filter used in the paper industry is made from PET monofilament. It is used in high temperature and humid environments for a long time. The PET filter is prone to hydrolysis reaction. Adding HyMax® hydrolysis stabilizer to the PET monofilament can extend the service life. It can reduce the frequency of shutting down to replace the filter screen, and significantly reduce the production cost.

【introduction of PET materials】

PET is a highly flexible, colorless, semi-crystalline resin with good dimensional stability, impact resistance, moisture resistance, alcohol and solvent resistance.

Most of PET is used to generate synthetic fibers (>60%, polyester), and the production of bottles is about 30%. It is a member of the polyester family, which together account for 18% of global polymer production, and is the fourth largest polymer after PE, PP and PVC.

PET plastic has a highly symmetrical molecular structure and a certain crystal orientation ability, so it has high film-forming properties. PET has good optical properties and weather resistance. Amorphous PET has good light transmittance, and PET has a higher crystallization temperature. High, slow crystallization speed, long molding cycle, large shrinkage after molding, poor dimensional stability, and brittle crystallization.

【advantages of PET materials】

- PET has higher strength and stiffness than PBT, and a higher heat distortion temperature

- Good gas insulation and moisture resistance

- Excellent electrical insulation

- Wide application range, -60℃~130℃

- PET has drop resistance, it can replace glass in some occasions

- Recyclable, resistant to microwave radiation

- PET is approved as food-grade safe plastic by FDA and other health agencies

【shortcomings of PET materials】

- The impact strength is lower than PBT, the crystallization speed is slow, and the crystallinity is worse than PBT

- affected by boiling water, easy to hydrolysis in high temperature and high humidity environment.

- Not resistant to strong alkalis, corrosion by ketones, aromatics, chlorinated hydrocarbons, dilute acids and alkalis at high temperatures> 60℃

- flammable

【solution with HyMax hydrolysis stabilizer】

Polyesters such as PET or PBT: The recommended dosage of HyMax 1010 hydrolysis stabilizer is 0.5-2.0phr. It can significantly improve the hydrolysis resistance of the material.

Adding about 1phr of HyMax®1010 hydrolysis stabilizer to PET can greatly increase the tensile strength and elongation at break (121℃, 2kg/cm2) after damp heat aging. When in use, it is recommended to use side feeding equipment to add to reduce the loss of HyMax®1010, or directly use HyMax®M10 anti-hydrolysis masterbatch.

Add HyMax 1010 hydrolysis stabilizer to PET monofilament filter of paper machine

In the processing of PET or PBT materials, adding 0.5 phr of HyMax® 1010 can be used as a protective aid to reduce the viscosity drop during the processing of polyester materials.

In the synthesis of polyester materials, adding a small amount of HyMax® 1010 can reduce the content of carboxyl end groups in the polyester.