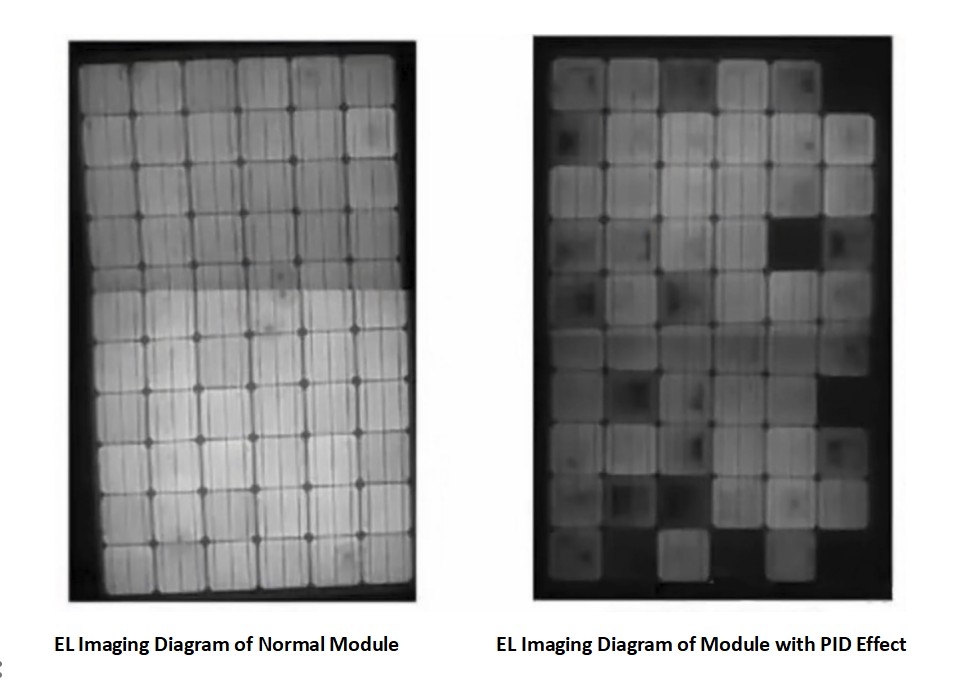

Are you frustrated by the mysterious power loss in your solar panels? Potential Induced Degradation (PID) is a silent thief, stealing efficiency and shortening the life of your valuable investment. Don't let your solar panels fall victim to this invisible enemy!

PID, or Potential Induced Degradation, is a common issue in solar panels where a high potential difference between the solar cell and the grounded module frame causes ion migration, leading to power loss. By understanding its causes, we can effectively combat this degradation.

We've seen firsthand how crucial it is to protect solar panels from degradation. When we started at Langyi 15 years ago in solar area, even then, the quest for durable materials was a core focus. Understanding how to keep these incredible power generators running efficiently is vital, and thankfully, we've found solutions that truly work.

What is PID in Solar Panels, Really?

Are you wondering why your perfectly good solar panels might be underperforming? Many people don't realize that a common issue, PID, could be the culprit, silently eating away at their energy production.

PID, or Potential Induced Degradation, is an electrical phenomenon where high voltage stress in solar modules causes a significant drop in power output. It primarily happens due to leakage currents caused by sodium ions moving from the glass and encapsulant into the solar cells, reducing their performance.

When we talk about PID, we are talking about something that can seriously impact the long-term viability of solar installations. From our perspective, working with functional additives for so long, we know that understanding the root cause is the first step to finding a good solution.

Understanding the Factors Leading to PID

PID is not just one thing; it is a complex interaction of several factors. Let us break down the main culprits that contribute to this power-sapping phenomenon.

| Factor | Description | Impact on PID |

|---|---|---|

| Voltage Stress | The high potential difference between the solar cell and the grounded module frame. | Drives the migration of ions, especially Na+ ions, into the cell structure. |

| Temperature | Elevated temperatures increase the mobility of ions within the encapsulant and glass. | Accelerates the rate of ion migration, making PID worse in hotter climates. |

| Humidity | High humidity creates a conductive pathway for leakage currents, especially on the module surface. | Facilitates the movement of charge and ions, enhancing the severity of PID. |

| Encapsulant Material | The type of polymer used (e.g., EVA, POE) and its resistance to ion permeation. | Encapsulants with higher ion permeability allow more Na+ ions to reach the solar cells. |

| Glass Composition | The presence and mobility of sodium ions in the soda-lime glass often used in solar panels. | Glass acts as a primary source of Na+ ions, which are then driven into the module under voltage. |

The combination of these elements creates a perfect storm for PID to occur. For example, in hot, humid environments with panels under high voltage stress, the degradation can be severe. Our goal at Langyi is always to provide solutions that address these fundamental issues.

Can Zirconium Phosphate (ZrP) Really Stop PID in Solar Panels?

Are you looking for a reliable way to stop your solar panels from degrading? It’s common to wonder if there’s a real, effective solution out there, and I can tell you that Zirconium Phosphate (ZrP) is a powerful answer.

Zirconium Phosphate (ZrP), specifically alpha-zirconium phosphate, acts as an excellent anti-PID additive by effectively scavenging and adsorbing sodium Na+ ions within the solar panel’s encapsulation film. This process prevents Na+ ions from migrating to the solar cells, thereby mitigating PID.

For years, we've worked on developing materials that solve real problems. When we started exploring solutions for PID, the unique properties of ZrP quickly caught our attention. It’s not just a filler; it’s an active participant in protecting the module.

How ZrP Fights Back Against Ion Migration

Understanding how ZrP works means understanding its chemical structure and how it interacts with harmful ions. It’s a smart solution based on fundamental material science principles.

Zirconium phosphate (ZrP) has a layered crystal structure, which gives it a large surface area and high ion exchange capacity. This unique structure allows it to effectively capture and trap positively charged ions. Specifically, the strong affinity of ZrP for Na+ ions is key. When Na+ ions try to migrate through the encapsulant film towards the solar cells, the ZrP particles act like tiny magnets, attracting and holding onto these ions. This prevents them from reaching the semiconductor material of the solar cell, which would otherwise cause electrical shunting and performance loss. The mechanism is similar to how a sponge absorbs water; ZrP absorbs the harmful ions, effectively neutralizing their threat. This not only maintains the electrical integrity of the solar cell but also ensures the long-term efficiency and reliability of the entire solar module.

The Adsorption Power of ZrP

The effectiveness of ZrP comes from its ability to chemically bind to sodium ions. This is not a temporary fix; it is a stable chemical interaction that permanently removes these ions from circulation.

| ZrP Property | Benefit in Anti-PID Application |

|---|---|

| High Surface Area | Provides numerous active sites for ion adsorption, increasing the capacity to trap Na+. |

| Layered Structure | Allows for intercalation of ions, effectively trapping them within the material matrix. |

| Cationic Exchange | Enables ZrP to exchange its own protons for Na+ ions, binding them strongly. |

| Chemical Stability | Ensures ZrP remains active and stable within the encapsulant over the long lifespan of the panel. |

| Non-Toxicity | Safe for use in materials that are exposed to environmental conditions. |

This table shows why ZrP is a preferred choice. Its properties directly counter the mechanisms of PID. At Langyi, we ensure our ZrP products leverage these characteristics to their fullest potential, giving our customers the best possible protection for their solar panels.

How Can We Make an Anti-PID Masterbatch with Zirconium Phosphate (ZrP)?

Are you wondering how to actually integrate this powerful anti-PID solution into your solar panel manufacturing? It's not enough to just know about ZrP; we need to know how to use it effectively.

To create an effective anti-PID masterbatch with Zirconium Phosphate (ZrP), we must carefully disperse high-purity ZrP powder into a compatible polymer carrier, such as EVA or POE. This process ensures uniform distribution of the ZrP additive within the encapsulation film, optimizing its Na+ scavenging capabilities and maximizing PID protection.

When we think about the practical application of our materials, we always consider the end-user. Making a masterbatch is about making it easy for manufacturers to get the benefits of our innovations. It's about providing a ready-to-use solution.

Key Steps in Developing a ZrP Anti-PID Masterbatch

Developing a masterbatch is a precise process that requires careful attention to detail. Our team at Langyi has refined these steps to ensure optimal performance.

Making an anti-PID masterbatch with ZrP involves several critical steps to ensure its effectiveness and compatibility with existing manufacturing processes. First, we select high-quality, fine-particle ZrP powder with a specific surface area to maximize its ion-scavenging capabilities. Next, we choose a polymer carrier resin that is compatible with the target encapsulation film, typically EVA (ethylene-vinyl acetate) or POE (polyolefin elastomer), to ensure good dispersion and adhesion. The ZrP powder is then pre-mixed with the polymer carrier. This mixture then goes through an extrusion process, where it is melted and thoroughly mixed, typically using a twin-screw extruder. The key here is to achieve a homogenous dispersion of ZrP within the polymer matrix without degrading the polymer or ZrP itself. Some other additives might be used together to make the composition performance better. Finally, the extruded strands are cooled and pelletized into a masterbatch. This masterbatch, with a high concentration of ZrP, can then be easily blended with the base encapsulant material by solar module manufacturers at their desired loading levels, ensuring uniform distribution of the anti-PID additive throughout the encapsulation film. This process ensures that the ZrP is evenly spread, allowing it to effectively capture Na+ ions and protect the solar cells from PID.

Factors for an Effective ZrP Masterbatch

To achieve the best results, several factors must be considered during masterbatch formulation and application. These details make a big difference in the final product's performance.

| Factor | Importance for Anti-PID Masterbatch |

|---|---|

| ZrP Purity and Particle Size | High purity ensures maximum active sites; fine particle size promotes better dispersion and more contact with ions. |

| Carrier Polymer Compatibility | Must be compatible with the encapsulant (EVA/POE) to ensure good blending and prevent phase separation. |

| Dispersion Uniformity | Even distribution of ZrP throughout the masterbatch and then the encapsulant is crucial for consistent PID protection. |

| Loading Concentration | The amount of ZrP in the masterbatch needs to be optimized to provide sufficient ion-scavenging without affecting film properties. |

| Processing Conditions | Temperature and shear rate during extrusion must be controlled to prevent degradation of materials and ensure proper dispersion. |

These factors are what we focus on at Langyi. Our commitment is to provide a functional additive that not only works but also integrates seamlessly into manufacturing processes.

Conclusion

PID is a serious threat to solar panel efficiency, but Zirconium Phosphate (ZrP) offers a robust solution. By scavenging harmful sodium ions, ZrP in anti-PID masterbatches ensures your solar panels deliver long-term, reliable power.