Due to its outstanding mechanical properties, chemical resistance, and durability, polyester monofilament has been widely used by many industries. In high-humidity and high-temperature environments, the performance of polyester monofilament can be affected over time. This article examines the causes of this degradation, possible solutions, and anti-hydrolysis as a way to address this issue.

1. What is polyester monofilament?

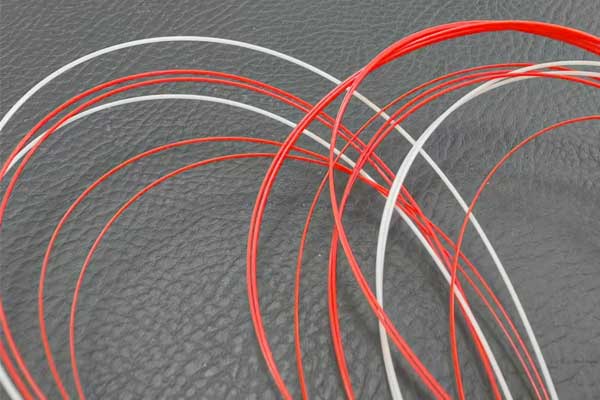

The polyester monofilament fiber is made from PET, a polyethylene terephthalate. It is used in many applications because of its flexibility, strength, and wear resistance.

- Industrial filters: For liquid and gas filtering.

- Papermaking cloth: Resistant to wear and tear in wet or abrasive conditions.

- Cables and ropes: High tensile strength for industrial applications.

Polyester monofilament is not without its limitations, especially in extreme environments.

2. Why does degradation occur?

Hydrolysis is the primary cause of degradation in environments with high temperatures and humidity. Water molecules cause hydrolysis, a chemical reaction that breaks down ester bonds within the polyester chain. This results in weakened mechanical properties. This degradation is primarily caused by:

- High humidity: Moisture molecules attack polymer chains to accelerate hydrolysis.

- Elevated temperatures: High temperature increases the rate of hydrolysis and can cause thermal degradation.

- Acidic and alkaline environments: Extreme pH conditions catalyze hydrolysis further.

Reaction Mechanism: Ester Bond Cleavage

The ester bond (-COO) in polyester is susceptible to hydrolytic attack. The following steps are involved in the reaction mechanism:

- The polymer matrix is penetrated by water molecules.

- Water breaks the ester bond into an alcohol (OH) and carboxylic acid.

- The repeated cleavages of ester bonds reduce the molecular weight and mechanical strength.

See more about what is hydrolysis?

3. Effects of Degradation

The following problems can occur when polyester monofilament is hydrolyzed:

- Loss of tensile strength.

- Brittleness and cracking.

- Reduced chemical resistance.

- Reduced service life of products.x

The material is not suitable for use in demanding industrial or environmental conditions if it does not receive proper stabilization.

4. How to improve chemical stability

There are several ways to improve the chemical stability in environments with high temperatures and humidity.

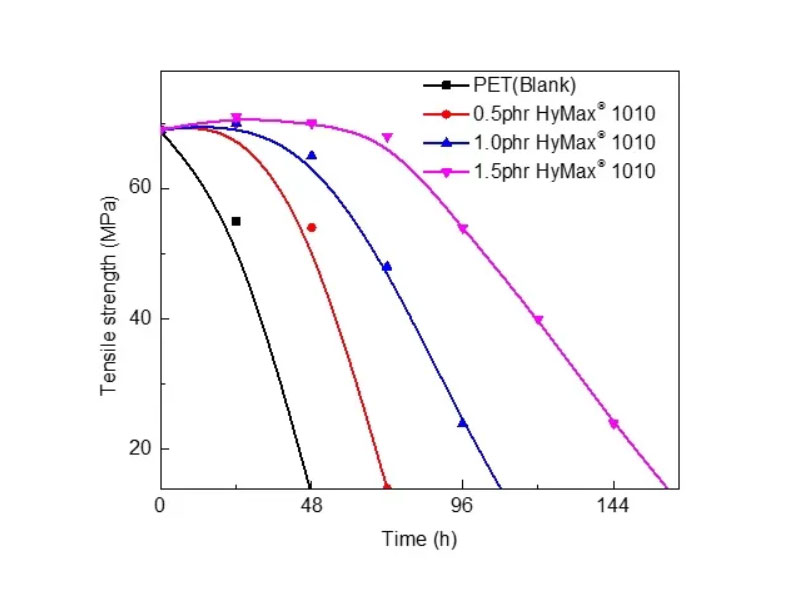

a. Use of anti-hydrolysis agents

Anti-hydrolysis additives are additives which stabilize the polyester structure while inhibiting the hydrolysis reaction. They function by:

- Reacting with water molecules to stop them attacking the polymer.

- Increasing the resistance of ester bonding in polymer chains.

b. Surface treatments

Monofilament can be protected from chemical and moisture attack by applying protective coatings like silicone, fluoropolymers, or polyurethane.

c. Copolymerization and blending

Stability can be improved by adding hydrolysis-resistant monomers to the polymer or blending it with other stable polymers, such as polyamide or polytetrafluoroethylene (PTFE).

d. Environmental control

Reduce degradation by limiting exposure to extreme temperatures and humidity through optimal storage and use conditions.

5. Case Studies and Applications

Industrial filters

The service life of industrial filters that are exposed to high levels of humidity can be significantly extended by adding anti-hydrolysis agents to the polyester monofilament.

Papermaking cloth

Anti-hydrolysis agents have proven to be effective in papermaking cloths where monofilaments of polyester are constantly exposed to water or mechanical stress. This method not only increases resistance to hydrolytic degrading but also extends operational life of the cloth and reduces replacement costs.

6. How to Use Anti-Hydrolysis Agents

The following methods can be used to integrate anti-hydrolysis agents into the production of polyester monofilament:

a. Added with anti-hydrolysis agent

The anti-hydrolysis agent can be added directly to the polymerization procedure, ensuring even distribution of the agent throughout the matrix. This method is very effective, but it requires that the reaction conditions are precisely controlled to ensure compatibility.

b. Added with anti-hydrolysis masterbatch

The concentration can be adjusted by the manufacturer when using masterbatches that contain anti-hydrolysis agents. This method is flexible and can be used for a variety of applications.

7. Conclusion

Polyester monofilament can degrade in environments with high temperatures and humidity. This poses a challenge to its use in applications that require high performance. The chemical stability and durability can be improved by understanding hydrolysis mechanisms and implementing solutions, such as surface treatments, polymer modification, and anti-hydrolysis agents. These improvements ensure that the material is reliable and effective even in harsh environments such as industrial, marine, and other demanding conditions.