Are you looking for ways to control heat and light efficiently in your products or buildings? Do you want to optimize energy use while maintaining clarity? Near-infrared absorbing materials offer a revolutionary solution to these challenges.

Near-infrared (NIR) absorbing materials are substances that effectively absorb radiation in the near-infrared spectrum while allowing visible light to pass through. This unique property makes them invaluable for applications requiring heat management, such as thermal insulation in automotive and architectural glazing, and agricultural heat-shielding films.

When our team first learned about near-infrared absorbing materials, we were fascinated by their potential. It's not everyday you encounter a material that can selectively block heat while letting light beautifully shine through. This concept alone sparked many ideas for how we at Langyi could contribute to greener, more efficient technologies. We have seen the challenges industries face with heat management, whether it's keeping car interiors cool, reducing energy consumption in buildings, or protecting crops from excessive solar radiation. These materials promise to solve these issues, blending scientific innovation with practical, everyday benefits. Our focus is often on optimizing these materials for performance and ease of integration into various products.

What are IR Materials?

Are you encountering the term "IR materials" and wondering what it truly means? You might think it is just a generic term for anything that interacts with infrared light. It refers to a specific class of materials designed to interact with these wavelengths.

IR materials are substances specifically designed to interact with infrared (IR) radiation, either by transmitting, reflecting, or absorbing it. These materials are crucial for applications that involve heat management, thermal imaging, and optical communication, as they allow for precise control over the flow of infrared energy.

In the field of material science, "IR materials" is a broad term. It includes anything that engineers or scientists purposefully choose or design because of how it behaves when exposed to infrared light. Infrared radiation itself covers a wide range of wavelengths, from near-infrared (NIR), which is close to visible light, to far-infrared (FIR), which is associated more directly with heat. The interaction with IR light varies greatly depending on the material's atomic and molecular structure.

For example, some materials transmit IR light with minimal loss, making them ideal for IR optics like lenses or windows in thermal cameras. Others are excellent reflectors, used in spacecraft to manage temperature. Then there are IR-absorbing materials, which convert IR radiation into heat, and these are particularly interesting for energy efficiency applications. Our work often revolves around these absorbing materials, especially those that can be integrated into thin films or coatings. We help companies understand which specific "IR material" will best suit their needs, whether they need to block heat completely or selectively manage certain parts of the IR spectrum.

| Type of Interaction | Description | Example Materials | Common Applications |

|---|---|---|---|

| Transmission | Material allows IR radiation to pass through. | Germanium, Silicon, Zinc Selenide, Calcium Fluoride | IR lenses, thermal camera windows, fiber optics |

| Reflection | Material bounces IR radiation away from its surface. | Polished metals (gold, silver), specialized coatings | Thermal blankets, radiant barriers, mirrors |

| Absorption | Material takes in IR radiation, converting it into heat or other energy forms. | Some organic dyes, metal oxides (e.g., tungsten oxides) | Heat filters, thermal insulation, solar collectors |

| Emission | Material releases IR radiation, often as a result of being heated. | Any object above absolute zero, specialized emitters | IR heaters, thermal signatures |

How Many Types of IR Materials and Their Difference?

Are you wondering about the diversity within IR materials and what distinguishes them? You might think they all do the same thing. They each have unique properties for different applications.

IR materials can be broadly categorized by their primary interaction with infrared radiation: transmitters, reflectors, and absorbers. Transmitters allow IR to pass through, reflectors bounce it away, and absorbers convert it into heat, with key differences lying in their chemical composition, optical properties, and suitability for specific wavelength ranges.

From our experience, the classification of IR materials goes beyond just their interaction. It dives into the specifics of which part of the IR spectrum they interact with and how efficiently. For instance, when we talk about transmitting materials, we consider their clarity and refractive index in the IR range. Germanium or silicon might transmit well in the mid-IR but not in the visible spectrum. Reflecting materials are chosen for their high emissivity in the IR, often leveraging metallic surfaces or multilayer coatings to reflect heat away.

However, for us at Langyi, the most exciting category is absorbing materials. These are further differentiated by their absorption profile. Some absorb across a broad IR range, while others are highly selective, absorbing only specific wavelengths. For example, while some pigments might absorb IR broadly, a material like Cesium Tungsten Oxide is highly selective, absorbing mainly in the near-infrared, which is crucial for applications where visible light transparency is desired. This selectivity is what allows for innovations like clear thermal-insulating films. Without this nuanced understanding of material types, optimizing performance for a given application would be much harder.

| Type | Primary Function | Key Characteristics | Typical Materials |

|---|---|---|---|

| Transmitters | Allow IR radiation to pass through. | High transmittance in specific IR bands, low absorption. | Germanium, Silicon, ZnSe, Fluorides |

| Reflectors | Redirect IR radiation away from a surface. | High reflectance, often metallic or dielectric coatings. | Gold, Silver, Aluminum, dielectric multilayers |

| Absorbers | Convert IR radiation into other forms of energy (usually heat). | High absorption coefficient in specific IR bands. | Metal oxides (CsxWO3), organic dyes, carbon black |

| Emitters | Release IR radiation when heated. | Specific emissivity characteristics. | Blackbody-like surfaces, certain ceramics |

What Materials Absorb Infrared?

Are you trying to identify materials that effectively absorb infrared radiation for your project? You might think all dark materials absorb IR. While many do, the specifics are more complex.

Various materials absorb infrared radiation, including many organic compounds, water, carbon black, and certain metal oxides like V2O5 and CsxWO3. The specific wavelengths absorbed depend on the material's molecular structure and electron configuration, with some absorbing broadly and others selectively.

From my perspective in the functional additives field, the universe of IR-absorbing materials is quite diverse. When we look at the entire infrared spectrum, almost anything can absorb some amount of IR radiation. Organic materials, for example, absorb IR due to vibrational modes of their molecular bonds (C-H, O-H, etc.). This is why substances like water are strong IR absorbers. Black plastics or paints often absorb a broad spectrum of IR because they contain carbon black, which is an excellent, non-selective absorber. However, the real challenge, and where Langyi’s expertise comes in, is finding selective IR absorbers. These are materials that absorb certain IR wavelengths very strongly while being transparent to others, particularly visible light. For example, some specialized organic dyes can absorb IR. But for durable, high-performance applications like thermal insulation films, inorganic materials often perform better. Understanding these differences allows us to recommend the most effective and stable solutions.

| Material Type | Characteristics for IR Absorption | Typical Wavelengths Absorbed (µm) | Notes |

|---|---|---|---|

| Organic Compounds | Vibrational modes of molecular bonds (C-H, O-H, C=O). | Broad, typically 2.5-25 | Used in IR spectroscopy, some plastics. |

| Water | Strong absorption due to O-H stretching and bending vibrations. | Strong peaks at ~3 and ~6, and broader in far-IR. | Ubiquitous; influences many applications. |

| Carbon Black | Non-selective broadband absorption due to electronic transitions and particle size. | Very broad, effectively across entire IR. | Common pigment, good for overall heat absorption. |

| Metal Oxides | Electronic transitions, phonon absorptions, free carrier absorption. | Varies by oxide and doping. | Used for selective absorption, e.g., smart windows. |

| Rare Earths | Characteristic sharp absorption bands due to f-electron transitions. | Specific narrow bands. | Used in IR lasers, optical filters. |

What Materials Absorb Near-Infrared Light?

Are you specifically targeting the near-infrared (NIR) spectrum for absorption, needing to minimize heat ingress while preserving visible light? You might find it hard to choose the right material. Special materials excel in this unique challenge.

Materials that effectively absorb near-infrared (NIR) light while maintaining high visible light transparency are a specialized subset of IR absorbers. Key examples include certain organic dyes, copper compounds, and particularly, nano-sized metal oxides like Cesium Tungsten Oxide (CsₓWO₃), which exhibits excellent selective NIR absorption.

Our team at Langyi has done extensive research into NIR absorbing materials. This is a critical area because NIR is the part of the solar spectrum that carries a significant portion of solar heat, yet is invisible to the human eye. So, the goal is often to block this heat without darkening a window or film. Organic dyes can offer NIR absorption, but they often struggle with long-term stability when exposed to UV light or high temperatures. This limits their practical use in demanding applications. This is where inorganic materials, especially nano-sized metal oxides, really shine.

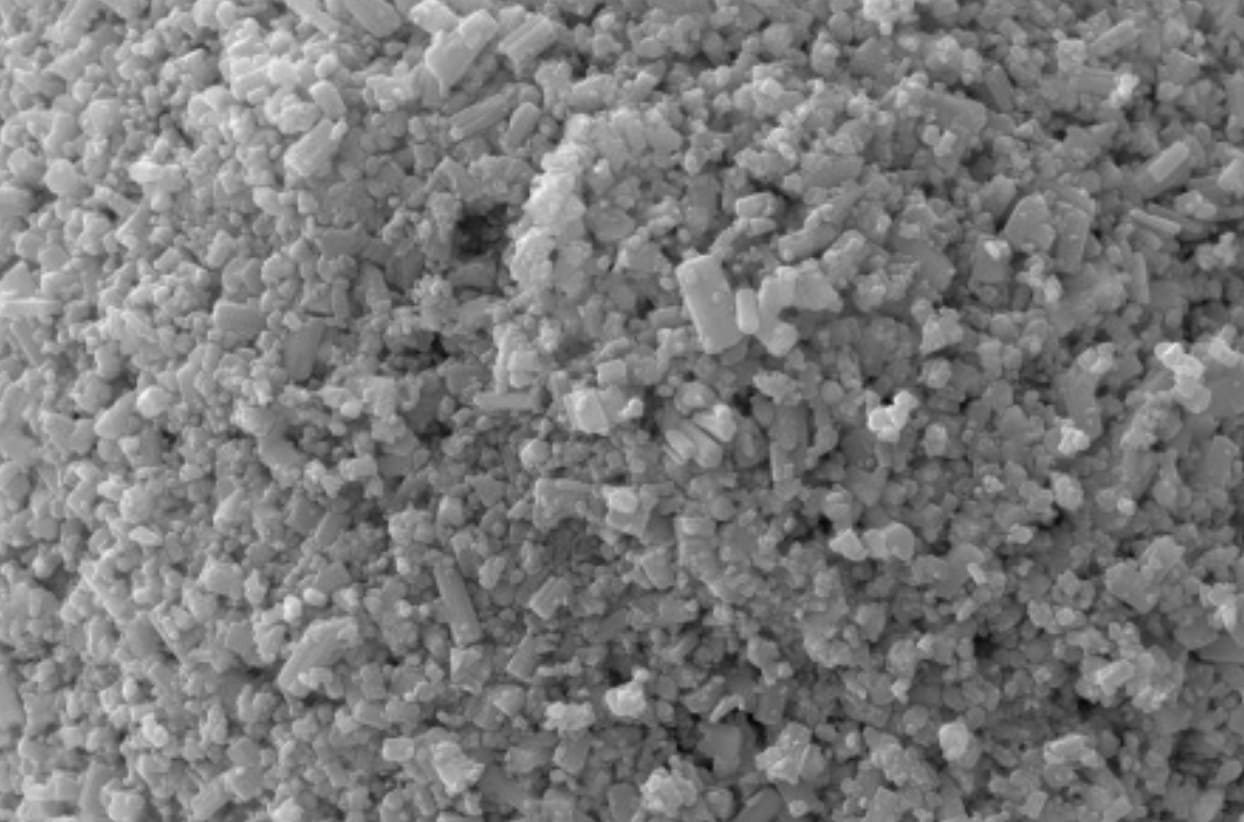

Cesium Tungsten Oxide (CsₓWO₃) is a prime example of this advanced generation of NIR absorbers. As we mentioned earlier, it can achieve extremely high NIR absorption rates—up to 95% or even over 97%—while maintaining impressive visible light transmittance. This selective absorption allows for clear films and coatings that provide superior thermal insulation. The challenge, of course, is effectively integrating these nano-powders, which appear blue-black, into films or coatings without compromising their performance or appearance. This is where Langyi's expertise in dispersion and masterbatch technology significantly adds value.

| Material | Key Characteristics for NIR Absorption | Visible Light Transmittance (Approx.) | Typical Appearance/Color (when in concentration) |

|---|---|---|---|

| Cesium Tungsten Oxide (CsₓWO₃) | Strong selective absorption in NIR, high stability, free carrier absorption. | High (80-90%+) | Blue-black (nano-sized) |

| Indium Tin Oxide (ITO) (doped) | Free carrier absorption in NIR, often requires doping. | High (70-85%+) | Transparent to slightly yellowish/blue |

| Specialized Organic Dyes | Tunable absorption bands, lower stability than inorganic. | Variable | Range of colors, often greenish/bluish |

| Antimony Tin Oxide (ATO) | Free carrier absorption, good electrical conductivity. | High (70-85%+) | Transparent to slightly bluish |

| Copper Compounds (e.g., Copper Phthalocyanine) | Charge transfer bands, specific absorption peaks. | Moderate to High | Green/Blue |

What’s the Main Application of Near-Infrared Absorbing Material?

Are you wondering where these specialized near-infrared absorbing materials are making the biggest impact? You might not realize how many daily items benefit from them. Their main application is controlling heat.

The main application of near-infrared absorbing materials is in smart thermal management, primarily to block solar heat radiation while allowing visible light to pass through. This translates into widespread use in automotive heat-insulation films, architectural thermal-insulation glazing, and agricultural heat-shielding films.

From my years at Langyi, it's clear that the driving force behind the demand for NIR absorbing materials is energy efficiency and comfort. Take automotive heat-insulation films as an example. I remember when cars would get scorching hot inside on a sunny day. By incorporating NIR absorbers (like Cesium Tungsten Oxide) into PET automotive films, we can drastically reduce the heat absorbed through car windows. This means less reliance on air conditioning, saving fuel, and a more comfortable ride—a win-win situation.

For architectural thermal-insulation glazing, the principle is similar. Buildings consume immense amounts of energy for cooling. NIR-absorbing layers in windows, often embedded in EVA or PC, help maintain indoor temperatures. This reduces energy bills and enhances occupant comfort.

Then there's agricultural heat-shielding films, typically made from PE. In many regions, excessive sun can damage crops. These films protect plants from overheating while still allowing essential light for photosynthesis. The challenge for these applications is often the uniform dispersion of the nano-sized blue-black powder. Improper dispersion can lead to hazy films or reduced performance. Some manufacturers, including Langyi, have developed masterbatch technology to mix these additives directly into plastic raw materials, ensuring a consistent, high-performance product and overcoming those dispersion hurdles.

| Application Type | Material Used (Typical) | Key Benefit of NIR Absorption | Real-World Impact |

|---|---|---|---|

| Automotive Heat-Insulation Films | PET films with CsₓWO₃ | Reduces interior temperature, lowers AC usage, improves fuel efficiency. | More comfortable car interiors, reduced carbon footprint. |

| Architectural Thermal-Insulation Glazing | EVA or PC with CsₓWO₃ | Decreases heat gain through windows, cuts cooling costs. | Energy-efficient buildings, enhanced occupant comfort. |

| Agricultural Heat-Shielding Films | PE films with CsₓWO₃ | Protects crops from overheating, prevents sun-scald, optimizes growth. | Increased crop yield, better resource management. |

| Display Filters | Various polymers with NIR absorber | Improves contrast, reduces glare from ambient NIR. | Better visibility for screens in bright environments. |

| Security/Privacy | Specialized films/coatings | Allows one-way vision in near-IR, hides objects from NIR cameras. | Confidentiality in sensitive areas, surveillance. |

Conclusion

Near-infrared absorbing materials are essential for managing heat and light effectively. They enable energy efficiency and comfort in diverse applications. Langyi specializes in providing solutions like CsₓWO₃ to meet these evolving needs.