Additives play an important role in polyester monofilaments production. Today, let’s investigate evaluation methods used to assess their compatibility with monofilament polyester production as well as comprehending hydrolysis-resistant agent applications within them.

Importance of Evaluating Compatibility between Additives and Polyester Monofilaments

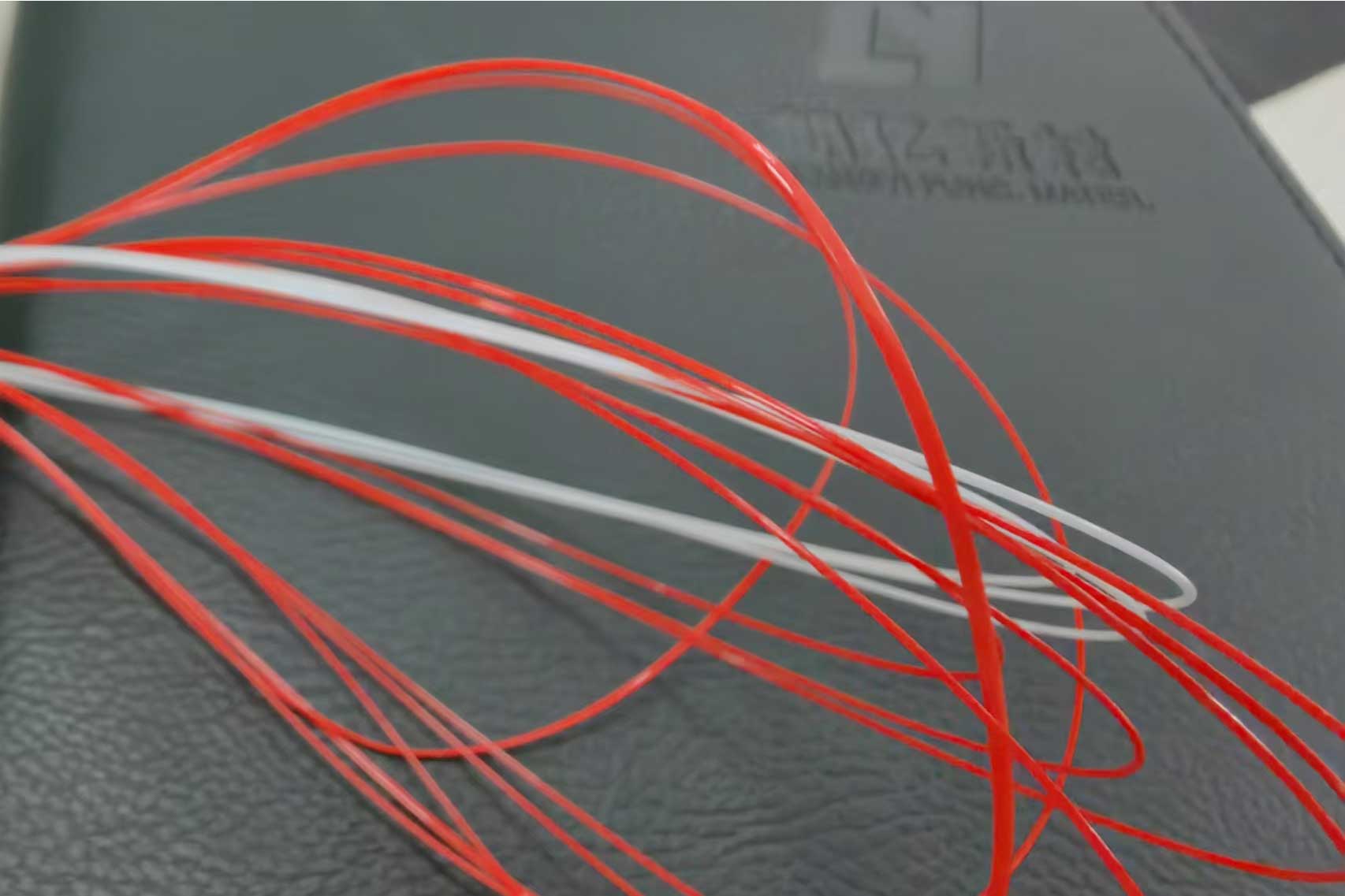

Polyester monofilaments have been widely used across textiles and industry with their ability to enhance various properties such as durability. When adding additives, their goal is to optimize those properties; however, poor compatibility may cause performance degradation or aesthetic flaws in monofilaments; good compatibility helps ensure additives contribute effectively and maintain stable monofilament quality.

Methods for Evaluating Compatibility of additives in polyester monofilaments

A. Theoretical level

- 1. Chemical Structure Fit

Starting with chemical structure, when an additive shares similarities or similar functional groups with polyester, their molecular structures will more readily blend together. For instance, ester groups found in some additive molecules could interact with ester bonds in polyester to some degree and improve compatibility. At the same time, matching of polarity is also crucial; when its affinity matches that of polyester polymers then the affinity increases significantly; preliminary judgments can be made using calculations such as dipole moments and solubility parameters to make preliminary assessments.

- 2. Molecular weight influencing factors

Polyester systems that utilize additives with moderate molecular weight tend to be more evenly dispersed; excessively large molecular weight will hinder dispersion, leading to uneven local concentrations; while excessively small molecular weight increases migration or volatilization concerns, thus diminishing long-term stability of monofilament performance.

B. Experimental detection methods

- 1. Thermal Analysis Technology

DSC can uncover the mysteries surrounding additives’ interaction with polyester. When these two elements work in harmony, their compatibility can have a noticeable impact on its thermal performance parameters such as glass transition temperature (Tg) and melting point (Tm). Meanwhile, thermogravimetric analysis (TGA) allows us to measure how additives contribute to thermal stability; when compatible, additives could increase thermal decomposition temperature while decreasing heat loss.

- 2. Microscopic Observation Methods

Both scanning electron microscopy (SEM) and transmission electron microscopy (TEM) provide visual evidence of additive dispersion within polyester monofilaments. Uniform dispersion without any signs of agglomeration or phase separation is evidence of good compatibility; for nanoscale additive research TEM’s role becomes especially evident.

- 3. Mechanical Property and Solubility Test

Mechanical property tests such as tensile, bending and impact can provide indirect indication of compatibility; when this relationship is positive, mechanical properties remain stable or improved. Solubility tests measure affinity between additives and polyester from a solvent perspective and data such as solubility parameters or mixing heat can serve as quantitative evaluation criteria.

C. Practical Application Verification

- 1. Monitoring of Production Process

Throughout production, observe the influence of additives on performance. Additives with good compatibility should disperse evenly into polyester melt without creating filter clogging issues and bubble formation, thus guaranteeing stable processing technology.

- 2. Investigation of Long-term Stability

To investigate long-term stability of polyester monofilaments formulated with additives under various environments, conduct long-term storage tests and accelerated aging tests to assess their compatibility is necessary. If they match well together, their monofilament should maintain performance over an extended period, without discoloration or embrittlement occurring as adverse side effects.

- 3. Assessing Actual Use Effect

In actual product applications, when wear resistance and dyeing performance meets expectations in textile applications or strength and corrosion resistance in industrial settings, this indicates that additive and polyester have good compatibility.

Hydrolysis resistant agents for polyester monofilaments

Mechanism of Action

Polyester monofilaments can become susceptible to hydrolysis in humid environments or over extended use, and hydrolysis resistant agents react with water molecules or acidic substances generated during hydrolysis in order to minimize damage to polyester molecular chains. Common examples are carbodiimide-based solutions; they capture any generated carboxyl groups while simultaneously inhibiting further catalytic hydrolysis reactions, thus improving hydrolysis resistance of polyester monofilaments.

Applications Benefits

- 1. Extending Service Life

For outdoor textile applications like sunshade nets and ropes, adding hydrolysis resistant agents can make polyester monofilaments resistant to rainwater erosion and rainwater erosion, thus increasing their lifespan over time and decreasing costs and resource waste associated with replacements.

- 2. Maintain Stable Performance

In industrial fields and applications like conveyor belts and filters, hydrolysis resistant agents help preserve strength, dimensional stability and other properties of polyester monofilaments to ensure smooth running equipment.

Synergy With Other Additives

Hydrolysis resistant agents may work synergistically with other additives such as stabilizers and lubricants to provide better protection of polyester monofilaments from multiple factors including heat, light and hydrolysis; cooperating with lubricants helps improve processing performance without diminishing their hydrolysis resistance effect.

Evaluation and application of compatible additives and polyester monofilaments as well as appropriate hydrolysis resistant agents are keys to improving quality and performance of polyester monofilaments. With scientific methods and efficient applications, we can make polyester monofilaments play their great value across a range of fields.

See more about applications in polyester monofilament:

- Technical key points of paper machine dryer screen and tips on its application

- How to improve the chemical stability of polyester monofilament?

- The Importance of Stabilizers and Anti-Hydrolysis Agents in Polyester Monofilament Production Processes

- Application of Anti-hydrolysis Agent in Biobased Polyester Monofilaments