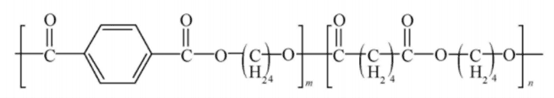

PBAT, with the full name polybutylene adipate terephthalate, has the following structural formula. It belongs to petrochemical-based biodegradable plastics and has become one of the very active degradable materials in research and market application at present.

PBAT is a thermoplastic biodegradable plastic with excellent biodegradability and is often used as a blend with PLA for packaging films, bags, agricultural films, disposable food and beverage utensils, etc. PBAT has similar mechanical properties to PBT, with good ductility, elongation at break, heat resistance and impact resistance.

PBAT has both biodegradable properties and mechanical properties, making it one of the stars in the field of biodegradable plastics. In actual use, the hydrolysis resistance of PBAT materials is relatively poor, and there are a large number of ester bonds in its molecular structure, which can easily react with water molecules in the air, thus causing ester bond breakage and degradation of material properties; especially under high temperature and high humidity, the hydrolysis aging phenomenon is more obvious. Therefore, it is of great significance to improve the hydrolysis resistance.

-1.jpg)

As an energy-efficient anti-hydrolysis additive, carbodiimide is often used in the anti-hydrolysis modification of polyester-based materials. Carbodiimide anti-hydrolysis agents can react with the carboxyl groups generated by hydrolysis to produce urea compounds without side effects, effectively inhibiting the hydrolysis process of ester groups.

As a professional supplier of carbodiimide products, Langyi New Material has developed a variety of anti-hydrolysis products to meet the application needs of different scenarios. For the hydrolysis problem of PBAT, Langyi New Material also has specialized solutions. We have developed both monomeric and polymeric anti-hydrolysis agents, which can effectively improve the anti-hydrolysis performance and comprehensive mechanical properties of PBAT.

For example, with the addition of 0.5% monomeric anti-hydrolysis agent HyMax®1010 to PBAT material, after 12 days aging comparison, it was found that its elongation at break was 4.5 times higher than that of PBAT material alone.

Langyi New Material has been deeply engaged in the segment of anti-hydrolysis for many years, and has accumulated a lot of solutions in related application fields, providing customers with the whole life cycle of production dissimilarity services. To learn more about anti-hydrolysis solutions, please contact us.