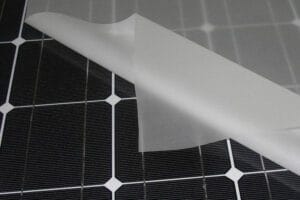

In the process of achieving a circular economy, solar energy plays an important role in the current and future energy mix as a renewable energy source. Frames are crucial components of solar photovoltaic modules, serving to secure and seal solar cells, enhance module strength, and facilitate transportation and installation. The performance of frames directly affects the installation and lifespan of the solar modules.

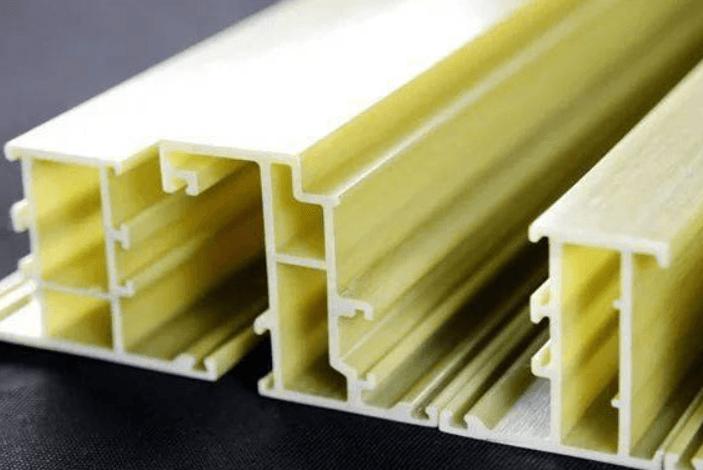

Traditionally, the majority of photovoltaic module frames have been made of aluminum alloy profiles. With the rapid growth of the photovoltaic industry, the demand for aluminum in photovoltaics has also increased year by year. The upstream material for aluminum alloy profiles is electrolytic aluminum, and the production process of electrolytic aluminum consumes a large amount of electricity, resulting in significant carbon emissions.

Due to the rapid growth in demand and limited capacity expansion, photovoltaic module manufacturers have been searching for materials with better performance and competitive costs to replace aluminum alloys. This is not only to control material costs but also to reduce the use of high-energy-consumption materials in the conversion of solar energy into sustainable energy. Polyurethane, as a commonly used material, has been widely adopted in the manufacturing of photovoltaic frames to provide structural support and protection for solar panels. However, polyurethane materials may undergo hydrolysis during long-term use, leading to performance degradation and reduced lifespan. To overcome this issue, researchers have introduced anti-hydrolysis agents to enhance the durability of polyurethane photovoltaic frames and extend their lifespan. This article will discuss the application of anti-hydrolysis agents in polyurethane photovoltaic frames and their potential advantages.‘’

Impact of Hydrolysis on Polyurethane Photovoltaic Frames

Polyurethane materials may undergo hydrolysis reactions when exposed to factors such as moisture, ultraviolet radiation, and temperature variations in the environment. This can result in a decrease in the physical properties of polyurethane, such as weakened strength, reduced weather resistance, and surface cracking. For photovoltaic frames, hydrolysis may cause the frames to lose structural support and integrity, thereby affecting the installation and use of solar panels.

Introduction of Anti-Hydrolysis Agents

To address the hydrolysis issue in polyurethane photovoltaic frames, researchers have started to introduce anti-hydrolysis agents. Anti-hydrolysis agents are additives that resist water intrusion and hydrolysis reactions. They can form chemical bonds with polyurethane materials, stabilizing the structure of polyurethane and providing an additional protective layer to slow down hydrolysis.

Advantages of Anti-Hydrolysis Agents

The introduction of anti-hydrolysis agents in polyurethane photovoltaic frames has the following potential advantages:

Enhanced Weatherability and Durability:

Anti-hydrolysis agents can provide additional weather resistance and durability, allowing polyurethane photovoltaic frames to better withstand environmental erosion. They can reduce structural damage caused by hydrolysis, maintain the integrity and stability of frames, and thus extend the lifespan of photovoltaic frames.

Improved Mechanical Performance:

The introduction of anti-hydrolysis agents can enhance the mechanical performance of polyurethane photovoltaic frames. By forming cross-linking structures with polyurethane, anti-hydrolysis agents can increase the strength, rigidity, and impact resistance of frames, making them more capable of withstanding external stresses and vibrations.

Protection of Photovoltaic Modules:

One of the primary functions of polyurethane photovoltaic frames is to protect solar panels. The use of anti-hydrolysis agents can form an effective barrier, preventing moisture, dust, and other contaminants from entering the interior of photovoltaic modules, thereby maintaining their efficient operation and reducing performance degradation.

Selection and Application of Anti-Hydrolysis Agents

The selection of suitable anti-hydrolysis agents is crucial for the performance of polyurethane photovoltaic frames. Researchers typically consider factors such as the chemical stability, compatibility with polyurethane, weather resistance, and cost of the anti-hydrolysis agents. The appropriate anti-hydrolysis agent should be chosen based on specific environmental conditions and expected lifespan, and it should be correctly added and blended during the manufacturing process.

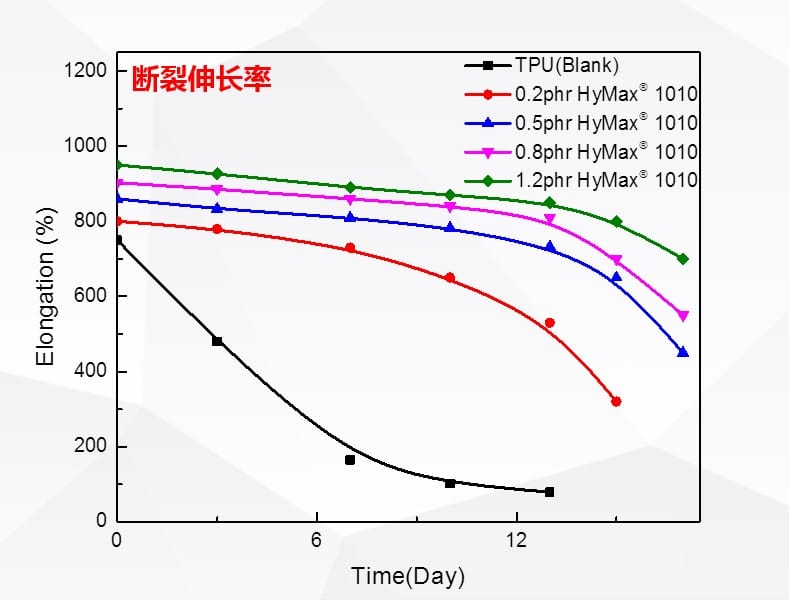

Testing effects of anti-hydrolysis agent in PU products

HyMax® 1010, an anti-hdyrolysis agent, is developed and manufactured by Langyi Functional materials. HyMax® 1010 can significantly improve the hydrolysis resistance of PU materials. With addition amount increasing, the hydrolysis resistance can be improved, the recommended addition amount is ≥0.5%.

HyMax 1010 in TPU

Conclusion

The introduction of anti-hydrolysis agents brings significant advantages to polyurethane photovoltaic frames, including improved durability, extended lifespan, and enhanced protection of photovoltaic modules. With the rapid development of the renewable energy industry, the demand for high-performance and reliable solar photovoltaic systems continues to increase. By using anti-hydrolysis agents, the hydrolysis resistance of polyurethane photovoltaic frames can be improved, enhancing the reliability and longevity of the systems and promoting widespread applications of solar photovoltaic technology in the field of sustainable energy.