Polylactic acid (PLA), as a completely degradable polymer material, is called “green plastic” and has good biodegradability, which can be completely degraded by microorganisms in nature after use, eventually producing carbon dioxide and water, without polluting the environment.

PLA also has good mechanical and physical properties and is suitable for various processing methods such as blow molding and injection molding. It can be made into fibers, films, blocks and boards for processing.

The market prospect of PLA is very promising for various plastic products from industrial to civil use, including food packaging, fast food lunch boxes, non-woven fabrics, agricultural fabrics, health care fabrics, wipes, sanitary products, outdoor UV protection fabrics, tent fabrics, ground mats, etc.

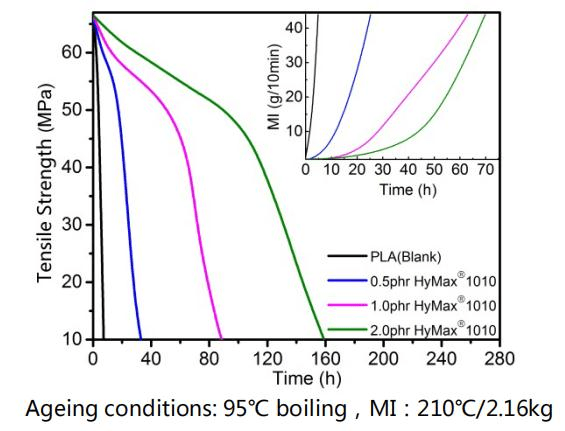

As a degradable plastic, the degradation rate of PLA in daily use has become a concern, especially the problem of fast degradation rate in high temperature and high humidity conditions, which affects the application of PLA plastic in many aspects. Therefore, how to reduce the degradation rate of PLA plastics and achieve controlled degradation is the key in the application of PLA products.

Causes of PLA spontaneous hydrolysis

The degradation of PLA resin in air is mainly due to the hydrolysis after moisture absorption. The fast moisture absorption rate and high equilibrium moisture absorption create the conditions for PLA resin hydrolysis.

The industrially produced non-medical PLA itself contains unreacted monomers and zwitterions, which are more prone to absorb water, and the monomers are prone to hydrolyze after absorbing water to produce acetolactic acid. The end carboxyl groups of acetolactic acid and zwitterions lower the internal pH of PLA. The amount of end carboxyl groups of hydrolysis products gradually increases, accelerating the rate of hydrolytic degradation. They are the catalyst for further accelerated hydrolysis and will produce autocatalytic phenomenon. Prior technic to solve the fast degradation rate of PLA resin currently is using crystallization and capping methods.

PLA crystallization technology to improve the durability of PLA resins

1. From the aspect of raw material synthesis, the stability of raw material resin is ensured by the preparation of high purity propylene cross ester.

2. the use of capping agents to ensure the stability of PLA resin end groups.

3. The use of anti-hydrolysis agent.

4. Adequate drying, moisture content <250ppm

Crystallization makes PLA molecules align neatly and improves the hydrolysis resistance of PLA, but does not completely change the hydrolysis resistance of PLA. Within the PLA material, the crystalline part has a slow hydrolysis rate while the amorphous part has a fast hydrolysis rate. So the higher the crystallinity, the stronger the PLA hydrolysis resistance.

The present technology of capping PLA resins is to improve the hydrolysis resistance by adding carbodiimide. The carbodiimide anti-hydrolysis agent is a highly efficient and durable anti-hydrolysis agent that can effectively capture the terminal carboxyl groups of PLA molecules and prevent the rapid decomposition of PLA molecules.