What is leather finishing agent?

The leather is affected by external force, sunlight, weather and other conditions, causing it to fade, wear or lose its original luster. This requires the use of leather finishing liquid to achieve the purpose of complementary color. After finishing, the surface of the leather garment will have a certain luster and uniform color, and a protective coating will be formed on the leather surface.

The function of leather finishing agent

The function of leather finishing agent is to make leather products have beautiful appearance, comfortable hand feeling and firm fixation after finishing.

The main substance in the leather finishing agent is the adhesive. It can form a uniform and transparent film on the leather surface. This film can attach the dyes, pigments and other ingredients in the coating agent to the leather surface, so that the surface of the leather is smooth and looks beautiful. It must also be heat-resistant, cold-resistant, water-resistant, organic solvent-resistant, dry and wet-resistant, and have ductility.

But so far, no coating agent can have all the above properties. Therefore, in practical applications, two or three film-forming materials including crosslinking agents are usually used at the same time to meet the comprehensive performance requirements of the coating.

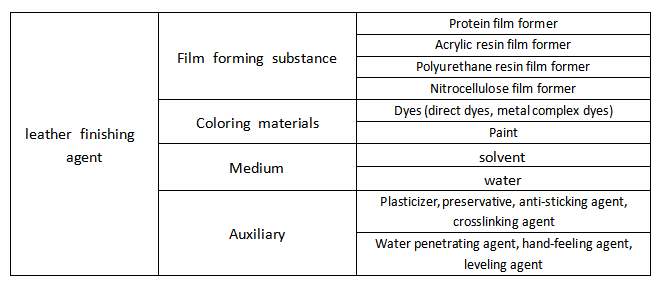

Composition of leather finishing agent

Leather finishing agent generally consists of four parts, namely film-forming material, coloring material, medium and auxiliary agent.

1. Film-forming substances

Film-forming substances are also called film-forming agents or adhesives. The most common use is resin, which is the main component of the coating liquid. It is used to form a uniform and transparent film on the surface of the leather together with coloring materials and coating additives. It has the following characteristics:

(1) Strong adhesion, resistance to friction and not easy to fall off.

(2) It has certain elasticity, softness and extensibility to avoid cracking.

(3) It has good mutual solubility for coloring materials and additives, without separation and precipitation.

(4) It has good air permeability.

(5) After filming, it has certain gloss and weather resistance properties, which can protect the leather surface.

The following types of film-forming substances are commonly used in the leather care industry:

1) Acrylic resin film former

Acrylic resin is the most widely used and widely used in leather finishing agents. It can blend coloring materials well. After being mixed with pigment paste, it has strong adhesion to leather and has good film-forming properties. The film formed is transparent, soft and with rich elasticity.

The specially treated acrylic filled resin is used for leather finishing, which can penetrate into the leather board and improve the loose surface of the leather board. The coating formed by acrylic resin has better light resistance, aging resistance, dry and wet rub resistance than cremein finishing agent, and better hygienic performance than nitrocellulose and polyurethane finishing agent.

The stability is good, and the milk wave will not appear layered and agglomerated after being placed for a period of time. After the film is formed, the film is resistant to high and low temperature (-25~25℃).

2) Polyurethane resin film former

Polyurethane resin is a leather finishing material that has been used more in recent years. It is characterized by rapid film formation, soft and smooth film feel, high elasticity and extensibility, strong adhesion, high and low temperature resistance, aging resistance, and good waterproof effect.

Adding a certain amount of polyurethane emulsion to the leather finishing agent can improve the weather resistance of the coating. Polyurethane resin film former can be a compensate for the “cold, brittle and hot sticky” of acrylic resin. It can improve the film-forming and physical performance the finishing agent, thus greatly improving the grade of finished leather.

3) Protein finishing film former

Protein finishing film former consists of casein and modified casein. Adding a certain amount of protein finishing agent to the leather finishing liquid can enhance the adhesion and increase the gloss of the coating, improve its high temperature resistance and air permeability, obtaining a comfortable feel and a certain filling effect.

4) Nitrocellulose finishing agent

Nitrocellulose finishing agent is mostly used in the top coating after leather finishing to increase the brightness of the coating and the water resistance, dry and wet rubbing resistance. It also has a good effect on solving the sticky feel of the acrylic resin coating. It can also be used in polymer finishes as an additional binder to increase leather’s water resistance and abrasion resistance. In addition, after careful drying, the adhesion of the leather during the hot ironing process can be reduced, and a very natural and warm hand feel can be obtained.

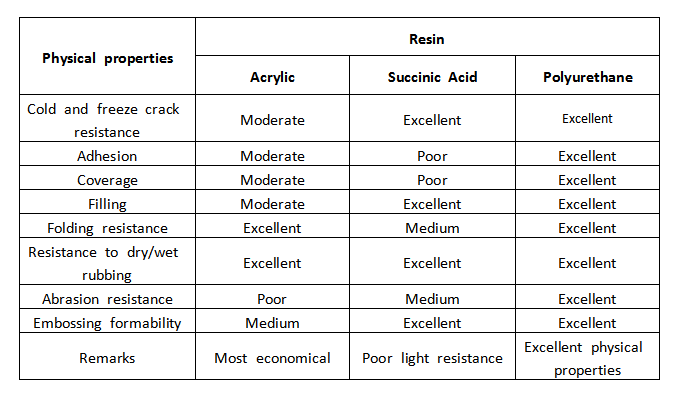

Comparison of common resin performance

2. Coloring materials

In the preparation of leather finishing liquid, a certain amount of coloring material is generally required. Coloring materials are composed of two types of substances, one is dyes and the other is pigments.

Dyes have a certain affinity for leather fibers, and can chemically interact with leather fibers and fix them on the leather surface. In the leather dyeing process, metal complex dyes are one of the most commonly used dyes with the above conditions.

The pigment itself has no affinity for leather, it relies on the adhesion of the film former to color the coating.

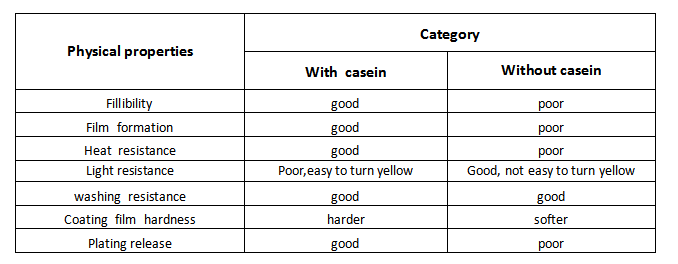

The most widely used are pigment pastes, commonly known as color pastes, which are divided into casein-containing color pastes and casein-free color pastes. The performance comparison of color pastes containing casein and without casein is shown in the following table:

Performance comparison of color pastes containing casein and without casein

3. Medium

The main function of the medium is to dissolve or dilute the film-forming substances and coloring materials, and adjust the concentration of the coating liquid according to needs. In the preparation of coating fluids, the commonly used medium are mainly water and solvents. The solvent uses butyl acetate, ethyl acetate, butanone, and dimethylformamide as the main raw materials.

4. Additives

In order to meet and improve the performance of the coating agent and achieve the desired coating effect, a certain amount of auxiliary agent is often added to the coating liquid.

Commonly used additives are as follows:

(1) Casein: It is a kind of protein, which improves the stability, brasion resistance and heat resistance of the coating.

(2) Wax liquid: increase the gloss of the coating and have a certain filling effect on the disability.

(3) Antiseptic: prevent the coating from decay and mold, generally used in summer.

(4) Penetrating agent: to make the resin or the bottom coating agent penetrate into the leather better, and improve the dispersion and leveling of the coating.

(5) Softener: improve the softness and flexibility of the coating.

(6) Fixing agent: improve the stability of protein and fix color.

(7) Feeling agent: increase the softness and smoothness of the coating feel.

(8) Leveling agent: improve the fluidity of the finishing agent.

Other commonly used leather care materials:

1. Sealing agent

The sealant is a milky white liquid, mainly composed of cationic resin and oil emulsion. It is mostly used for primer sealing of aniline leather, integrated fur or semi-aniline leather with heavier wear. After finishing, the film is more uniform and the penetration of the leather surface is shallow, which can make the leather plump and soft, maintain the original style of the leather, and enhance the waterproof function of the leather.

2. Primer adhesive

The primer adhesive is a polymer adhesive resin, which is mainly used for the bottom coating of leather to increase the adhesion of the leather board. It is suitable for the leather surface with poor penetration. Spraying the primer adhesive once before painting will prevent the leather board from cracking and falling after coating.

3. Crack surface repair agent

Cracked surface repairing agent is a polyurethane film-forming coating material. It is mainly used for leather cracking, bursting, cross-section, cracking, neckline, cuff wear and heavier wear parts as a primer.

4. Repair cream

Repair cream is divided into anionic repair cream and cationic repair cream, creamy white paste. It is used for repairing the wounds on the leather surface. It is required to be evenly painted during use to make the leather surface smooth.

5. Brightener

The brightener is mainly used for the top coating of leather to increase the gloss and feel of the coating, and play a role in fixing the color after the film is formed.

According to raw materials, it is divided into nitrocellulose fiber brightener, protein brightener, and polyurethane resin brightener.

According to solubility, it can be divided into water-soluble brightener, amphoteric brightener, and solvent-based brightener.

According to gloss, it can be divided into high-gloss brightener, medium-gloss brightener, and sub-gloss brightener.

6. Leather clothing retanning agent

It is a water-based multifunctional cleaning aid that can supplement the necessary nitrate elements lacking in leather fiber. Make leather garments soft and not stiff.

7. Leather fatliquoring softener

It is suitable for smooth, suede sheepskin, cowhide, and hard-washed leather that has been naturally aged and hardened for many years. It can add grease to the leather and make the leather board soft and plump. It is generally divided into water washing fatliquor and dry cleaning fatliquor.

8. Crosslinking agent

The crosslinking agent is a colorless or light yellow liquid. It can improve the wet rub resistance, abrasion resistance and high temperature resistance of the leather top coating. It is used in the primer and intermediate coatings to significantly improve the coating adhesion and embossing formability. It can be added to the finishing agent in a small amount.

9. Fading and release agent

It is suitable for changing the color or removing the original coating. The film removal effect is obvious. Just wipe the leather surface with a towel cloth with higher friction.

10. Adhesive materials

Some worn and scratched leather products need to be glued with adhesives before care. There are many types of adhesives, including natural rubber and synthetic materials.

11. Acidic materials

In the dyeing process of leather care, it is necessary to control the temperature, water volume, mechanical action and time of the dyeing, and to adjust the pH value of the dyeing solution in time to increase the dye uptake rate, usually by adding an appropriate amount of oxalic acid or other weak acid solutions. In addition, when washing leather goods, weak acids or acid salts are often used to neutralize the remaining alkalinity.