Polyurethane (PU) is a versatile material used in a wide range of applications, including footwear. PU shoe soles are popular due to their light weight, durability, and comfort. However, PU is susceptible to hydrolysis(What is hydrolysis), which can lead to degradation of the material over time. To address this issue, carbodiimide anti-hydrolysis agents have been developed for use in PU shoe sole formulations.

Reaction Mechanism

The hydrolysis of PU is initiated by the reaction of water with urethane or urea groups in the polymer. Carbodiimide anti-hydrolysis agents work by reacting with water to form an intermediate product, which then reacts with the urethane or urea groups to form a more stable product. This reaction mechanism effectively blocks the hydrolysis reaction and protects the PU from degradation.

Application Cases

Carbodiimide anti-hydrolysis agents have been widely used in the production of PU shoe soles. For example, a major shoe manufacturer in China used a carbodiimide anti-hydrolysis agent in their PU shoe sole formulation to improve the hydrolysis resistance of the material. The results showed that the use of the anti-hydrolysis agent significantly extended the service life of the shoe soles, reducing the need for frequent replacement and improving customer satisfaction.

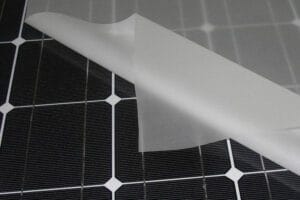

PU shoe sole

Another application case involved the production of PU adhesives for shoe sole bonding. The addition of carbodiimide anti-hydrolysis agents improved the water resistance of the adhesive, ensuring a strong and durable bond between the sole and the upper.

Application Effectiveness

The effectiveness of carbodiimide anti-hydrolysis agents in PU shoe sole formulations has been demonstrated in various studies. For example, a study conducted by a research team in South Korea found that the addition of a carbodiimide anti-hydrolysis agent to a PU shoe sole formulation improved the hydrolysis resistance of the material by up to 40%. The researchers also found that the anti-hydrolysis agent did not significantly affect the mechanical properties of the PU, indicating that it did not compromise the performance of the material.

Conclusion

Carbodiimide anti-hydrolysis agents have proven to be effective in improving the hydrolysis resistance of PU shoe soles and adhesives. The reaction mechanism of these agents effectively blocks the hydrolysis reaction and protects the material from degradation. Application cases have shown that the use of carbodiimide anti-hydrolysis agents can significantly extend the service life of PU shoe soles and improve customer satisfaction.