Application background:

With the growing global demand for renewable energy, solar panels are widely used as a clean and sustainable energy solution. Solar panels provide a reliable power supply for various applications such as residential, commercial and industrial buildings, agricultural uses, and power supply in remote areas by converting solar energy into electrical energy. However, solar panels can be damaged when exposed to humid environments and harsh weather conditions, which pose challenges to their performance and longevity.

The composition of the solar panel:

A solar panel is a composite structure composed of multiple components, each of which performs an important function to ensure efficient conversion of solar energy and stable output of electrical energy. The main components include:

Silicon solar cells: As a key part of photoelectric conversion, silicon solar cells convert light energy into electricity.

Silicon wafers: Silicon solar cells provide electrical output by connecting silicon wafers together to form a battery pack.

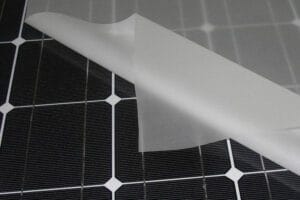

Backsheet: The backsheet is the protective layer on the back of the solar panel for support and protection.

EVA (Ethylene Vinyl Acetate) Film: EVA film is used to encapsulate solar cells and protect them from humidity and environmental influences.

PET (polyethylene terephthalate) backsheet film: A PET backsheet film sits on the outer layer of the backsheet for extra protection and durability.

Hydrolysis inhibitor is a chemical additive used in PET backsheet film. Its function is to increase the hydrolysis resistance of the PET back sheet film to resist the erosion of humid environment and moisture. The hydrolysis inhibitor will interact with the PET material to form a protective film, which can effectively prevent the penetration of water and the hydrolysis reaction of the backsheet film. This prolongs the life of the solar panel, keeps it performing consistently, and reduces the need for maintenance and replacement.

The application of hydrolysis inhibitor in PET backsheet film provides the following advantages:

Enhanced durability: The hydrolysis inhibitor can reduce the erosion of moisture on the backsheet film, improve its moisture resistance and weather resistance, and prolong the life of the solar panel.

Improve stability: The presence of hydrolysis inhibitors can prevent moisture penetration, reduce hydrolysis reactions, and enable solar panels to maintain stable performance under adverse environmental conditions.

Reduce maintenance costs: By improving the durability of PET backsheet films, hydrolysis inhibitors can reduce maintenance and replacement costs and increase the economics of solar panels.

In conclusion, the application of hydrolysis inhibitor in PET backsheet film is an important measure to protect solar panels from moisture erosion. It improves the durability and stability of the backsheet membrane, prolonging the life of the panel while reducing maintenance costs. In humid environments and harsh weather conditions, the application of hydrolysis inhibitors in PET backsheet films can maintain the stable performance and reliability of solar panels, ensuring that they can effectively convert solar energy into usable electrical energy for a long time.

In addition, the selection and application technology of hydrolysis inhibitors are also very critical. Professional suppliers such as Lanyi can provide customized hydrolysis inhibitor solutions, and provide customers with high-quality hydrolysis inhibitor products and technical support according to the characteristics and needs of PET backsheet films. With years of experience and expertise, we can tailor the addition method and concentration of hydrolysis inhibitors to ensure the best anti-hydrolysis effect.