Are your PLA products failing prematurely, especially in challenging environments? Do you want to unlock the full potential of this sustainable polymer? Using the right additives can significantly extend the service life of PLA1.

To extend the service life of PLA, especially against degradation caused by humidity and heat, specific additives like anti-hydrolysis agents2 (e.g., carbodiimides) are crucial. These additives protect the polymer chains from breaking down, enhancing durability and stability.

When we first started working with PLA, everyone was excited about its biodegradability3 and eco-friendly profile. However, we quickly realized that while biodegradability is a great feature for end-of-life, it also meant PLA could be susceptible to degradation during its intended service life, especially when exposed to moisture and heat. This susceptibility limited its applications. At Langyi, we recognized this challenge. We focused on developing solutions to make PLA more robust, ensuring it lasts as long as needed, but still degrades when disposed of properly.

What is PLA in Polymers?

Are you wondering what PLA is and why it's gaining so much attention in the world of polymers? You might just know it as a "green plastic." It is much more than that.

PLA stands for Polylactic Acid, a biodegradable and compostable thermoplastic polyester derived from renewable resources like corn starch, sugarcane, or tapioca roots. Unlike traditional petroleum-based plastics, PLA offers a more sustainable alternative due to its bio-based origin and end-of-life options.

From my perspective, PLA represents a significant step towards a more sustainable future for plastics. When I first encountered it, the idea of making plastic from plants was revolutionary. It's a linear aliphatic polyester. It is produced by the fermentation of plant sugars into lactic acid. This lactic acid is then polymerized into PLA. One of PLA's key advantages is its compostability. This means it can break down into natural components under specific conditions, reducing plastic waste. However, this inherent biodegradability is also its Achilles' heel in terms of service life. While great for composting, it means PLA is susceptible to hydrolysis—degradation by water. This degradation is accelerated by heat, which is a big concern for products used in warm, humid environments or during processing. For instance, in applications like food packaging or disposable tableware, having PLA that can withstand moisture and heat for its intended use period is crucial. Without protection, these products might lose integrity too quickly, leading to customer complaints or product failure. That's why understanding its properties and vulnerabilities is essential for its successful application.

| Feature | Description | Implication for Service Life |

|---|---|---|

| Bio-based Origin | Derived from renewable resources (corn, sugarcane) | Reduces reliance on fossil fuels, sustainability advantage. |

| Biodegradability | Breaks down in industrial composting facilities | Good for end-of-life, but can lead to premature degradation if exposed to moisture/heat early. |

| Thermoplastic | Can be repeatedly melted and reformed | Allows for diverse processing methods (injection molding, extrusion). |

| Hydrolytic Stability | Susceptible to degradation by water, especially at elevated temperatures | Limits use in high-humidity or high-temperature environments unless protected. |

Does PLA Break Down in Water?

Are you concerned about whether your PLA products will dissolve or degrade just by being exposed to water? You might think it is instantly biodegradable in any water. The reality is more nuanced.

Yes, PLA does break down in water, primarily through a process called hydrolysis. This degradation is significantly accelerated by higher temperatures and pH levels. While not immediate dissolution, prolonged exposure to water, especially warm water, will cause PLA to lose its structural integrity over time.

One of the common misconceptions I've encountered is that PLA magically disappears upon contact with water. It's not like sugar dissolving. The breakdown mechanism for PLA in water is hydrolysis. This is a chemical reaction where water molecules break the ester bonds in the PLA polymer chains. This process reduces the molecular weight of the polymer, leading to a loss of mechanical properties. Think of it like a chain. The water molecules break the links one by one. The chain becomes weaker and eventually breaks apart. This is why PLA products can be challenging in high-humidity or warm, wet conditions.

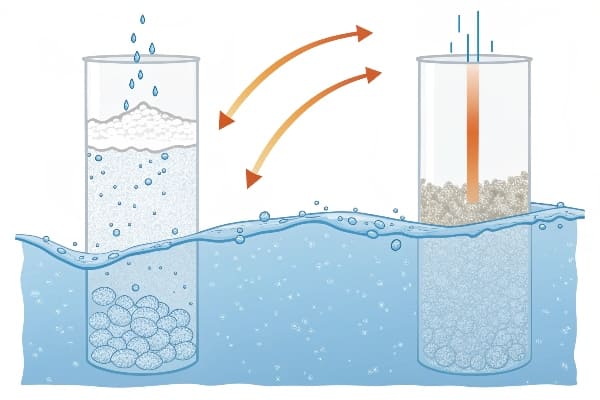

For example, during the production of PLA straws, they often need to pass through water for cooling and forming. This critical step can degrade the molecular chains if not properly managed, potentially leading to brittle straws that break easily. Similarly, PLA-based packaging for moist foods can degrade prematurely. This inherent susceptibility to hydrolysis is precisely why anti-hydrolysis agents are so crucial. They act as sacrificial agents or chain extenders, consuming the water or reacting with the newly formed carboxyl groups, thereby preventing the main PLA chains from breaking down. This protection ensures the product maintains its integrity throughout its intended service life.

| Factor | Impact on Hydrolysis | Consequence for PLA Service Life |

|---|---|---|

| Temperature | Higher temperatures significantly accelerate hydrolysis reaction rates. | Products in warm environments (e.g., hot beverages, humid climates) degrade faster. |

| pH Level | Both acidic and alkaline conditions can accelerate hydrolysis (acid or base catalysis). | Extreme pH environments can shorten product longevity. |

| Molecular Weight | Lower molecular weight PLA degrades faster. | Starting with high-quality PLA and preventing degradation during processing is key. |

| Crystallinity | Higher crystallinity4 can reduce the rate of hydrolysis to a certain extent. | Processing conditions that promote crystallinity4 can offer some protection. |

What is the Lifespan of PLA?

Are you curious about how long PLA products effectively last before they start to degrade? You might think it is just a few months. The actual lifespan can vary greatly.

The lifespan of a PLA product is highly variable. It depends on ambient conditions like temperature, humidity, and the presence of microorganisms. In typical indoor, dry conditions, PLA products can last for many years without significant degradation. However, in hot, humid, or composting environments, degradation can occur within months or even weeks.

When customers ask me about PLA's lifespan, I always emphasize that it's not a one-size-fits-all answer. For example, a PLA 3D-printed figurine sitting on a shelf in a climate-controlled room might last for decades with no noticeable change. However, a PLA-based disposable cup used for a hot drink and then left in a humid environment could show signs of degradation much faster. The key differentiator is the environment. PLA is designed to break down in specific industrial composting facilities, where the conditions (high temperature, high humidity, presence of microbes) are optimized for its degradation. Without these conditions, its breakdown is very slow. Our goal at Langyi is to ensure that PLA products last precisely for their intended service life, and no more. This means if a PLA food container needs to last for several weeks on a supermarket shelf, it should do so without becoming brittle or discolored. If a textile made from PLA needs to withstand laundry cycles and prolonged wear, it must maintain its integrity. This is where anti-hydrolysis agents become indispensable. They are the guardians of PLA's service life, protecting it until its intended use is over. They contribute to a more stable product quality, preventing premature failure.

| Environment Type | Typical Lifespan for PLA | Factors Influencing Breakdown Rate |

|---|---|---|

| Indoor, Dry | Years to Decades | Minimal degradation as conditions for hydrolysis/microbial activity are absent. |

| Outdoor (Ambient) | Months to a few Years (variable) | Exposure to UV, rain, temperature fluctuations, and microbes accelerates breakdown. |

| High Humidity/Warm | Weeks to Months | Accelerated hydrolysis due to moisture and elevated temperatures. |

| Industrial Composting | Weeks to Months (typically 6-12 weeks for full breakdown) | Optimized conditions (high temp, high humidity, active microbes) for rapid degradation. |

| Soil/Water (Natural) | Years to Decades (much slower than composting) | Slower breakdown due to varied conditions and absence of optimized microbial activity. |

How to Extend the Service Life of PLA with Additives?

Are you looking for practical ways to make your PLA products more durable and resistant to degradation? You might think it is a complex chemical process. It is primarily about choosing the right additives.

The most effective way to extend the service life of PLA, particularly in challenging high-humidity and high-temperature environments, is by incorporating anti-hydrolysis agents. These additives, such as carbodiimide-based compounds, protect the PLA polymer chains from hydrolysis by reacting with water or carboxylic end groups, thereby preserving the material's integrity and mechanical properties.

Based on my experience, the key to extending PLA's service life lies in combating its sensitivity to hydrolysis. This is especially critical during processing and for products used in non-ideal conditions. For example, in the production of PLA straws, the material goes through melt extrusion and then often into a water bath for cooling and shaping. This combination of heat and water is a prime environment for PLA chain scission. Without protection, the molecular weight might drop significantly, leading to brittle straws prone to cracking. This is exactly where our anti-hydrolysis agents, particularly those based on carbodiimide chemistry, come into play.

Carbodiimides act as chain extenders and anti-hydrolysis agents. They react preferentially with the carboxyl and hydroxyl end groups that are either present in the virgin PLA or formed during the initial stages of degradation. By reacting with these groups, they effectively "cap" the ends of the polymer chains, preventing further chain scission by hydrolysis. They can also scavenge any trace moisture present in the polymer melt. This dual action dramatically stabilizes the PLA. It maintains its molecular weight and mechanical properties throughout processing and its intended service life. This simple additive can make a profound difference. It turns a fragile PLA product into a robust one, suitable for a much wider range of applications.

| Additive Type | Mechanism of Action | Key Benefits |

|---|---|---|

| Anti-Hydrolysis Agent (e.g., Carbodiimide) | Reacts with water and/or carboxylic end groups, preventing chain scission. | Greatly improves hydrolysis resistance, maintains molecular weight, enhances mechanical properties. |

| Chain Extender (e.g., Carbodiimide) | Reconnects broken polymer chains, increasing molecular weight. | Improves toughness, melt strength, and processability. |

| Impact Modifier | Absorbs and dissipates energy, preventing crack propagation. | Increases impact strength and flexibility, reduces brittleness. |

| Plasticizer | Reduces intermolecular forces, making polymers more flexible. | Improves flexibility and processability, can affect mechanical properties. |

| UV Stabilizer | Protects against degradation from ultraviolet radiation. | Extends outdoor lifespan, prevents discoloration and embrittlement from UV exposure. |

Conclusion

Extending PLA's service life is crucial for its broader adoption. Using anti-hydrolysis additives significantly improves its durability. This makes PLA a more reliable sustainable material.

Explore the importance of PLA in sustainable materials and its benefits over traditional plastics. ↩

Learn how anti-hydrolysis agents protect PLA and enhance its durability in challenging environments. ↩

Understand the trade-offs between biodegradability and service life in PLA applications. ↩

Discover how crystallinity affects the stability and degradation rate of PLA. ↩