What are CPLA straws?

CPLA straws are made by heating PLA, absorbing heat and exothermically crystallising it into CPLA, which is a crystallised PLA straw that combines the safety and environmental friendliness of PLA material with the convenience of consumer use.

How are CPLA straws made?

CPLA straws are usually made from heat resistant polylactic acid, which is extruded into PLA straws and then crystallised to produce a heat resistant 100°C CPLA straw.

What are the advantages of CPLA straws?

No PBS added, high food contact safety, not only meet the national standard requirements, but also much higher than the national standard requirements. cpla straws in 95% ethanol solution migration is still less than the reported limit value of 3mg/d㎡ (national standard limit value is 10mg/d㎡)

▲ CPLA straws are heat resistant up to 95°C and above, and are universal for hot and cold use. While enhancing the consumer experience, CPLA straws are also conducive to shop staff operation without the need to make tube type distinctions.

▲ CPLA straws are round in diameter and the deviation of the hole diameter is reduced from 2mm in traditional PLA straws to less than 0.2mm, making it easier for customers to suck the material.

The CPLA straws have an increased compressive strength from 12N to more than 20N, making them harder and easier to pierce the sealing film, and the straws are less likely to flatten when the customer sucks on small ingredients.

▲ The shelf life of CPLA straws has been increased from 6 months to over 12 months for traditional PLA straws, which has a longer shelf life and is more resistant to ageing and is more conducive to inventory cost control for brands.

There are many factors that affect the crystallisation performance of CPLA, including internal factors such as the composition of the material, the regularity of the molecular chain, the molecular weight and the width of the molecular weight distribution, as well as external factors in the crystallisation process, such as additives, moulding parameters and processing techniques.

There are three main ways to improve the crystallisation properties of PLA:

The first is to add nucleating agents to increase the nucleation density;

Secondly, adding flexible molecules to weaken the interaction forces between PLA molecular chains, increase the mobility of chain segments, reduce the surface folding energy during crystal growth, and increase the crystal growth rate;

Thirdly, changing external conditions such as crystallisation temperature and crystallisation time can also achieve the purpose of improving the crystallisation performance of PLA.

PLA molecular chain activity is weak, and in the common industrial processing and moulding process, the moulding cycle is short, the temperature drops quickly, and the product is mainly in the amorphous state when it has not undergone modification treatment. Due to uneven local temperature changes, the product is opaque to translucent in different areas with different crystallinity, which seriously affects the quality of the product. Nucleating agents can effectively increase the nucleation density and shorten the nucleation cycle of the product, which has great potential for industrial applications. Depending on the source of the nucleating agent, the common nucleating agents for PLA can be divided into inorganic, organic, biomass nucleating agents and special nucleating agents.

Key additive for heat resistance in PLA – polycarbodiimide

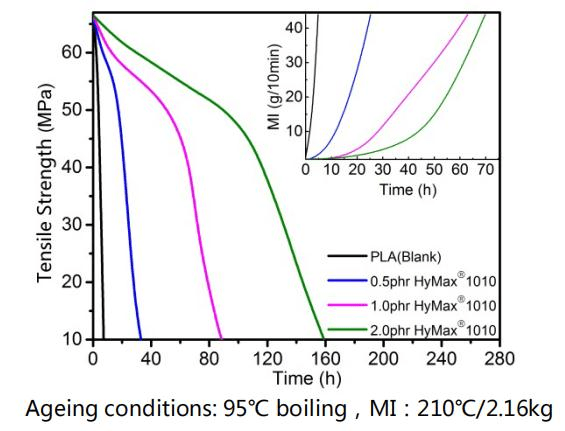

The addition of polycarbodiimide to CPLA helps to improve the hydrolysis of PLA and repair the broken molecular chains, thus improving the heat resistance and shelf life of the material. In application, with the addition of polycarbodiimide, the shelf life of CPLA staws improves from 6 months to 12 months.

Ageing test of PLA added with polycarbodiimide