Introduction

In the realm of outdoor gear, the integration of hydrolysis-resistant agents into polyester monofilaments has ushered in a new era of enhanced durability and performance. These agents, meticulously designed to combat the deteriorative effects of water-induced degradation, have emerged as a game-changer in the construction of polyester monofilaments used in outdoor equipment. This article delves into the multifaceted applications of hydrolysis-resistant agents in outdoor gear polyester monofilaments, underscoring their indispensable role in prolonging the lifespan and reliability of such products.

See more about anti-hydrolysis agent:

Enhanced Durability

The paramount advantage of incorporating hydrolysis-resistant agents into outdoor gear polyester monofilaments is the substantial enhancement of durability. Outdoor equipment is frequently exposed to moisture, which can lead to the hydrolysis of polyester fibers and consequent weakening. By effectively inhibiting the degradation of polyester monofilaments in the presence of water, hydrolysis-resistant agents effectively extend the operational lifespan of gear such as ropes, cables, and tent materials, ensuring they remain robust and reliable even during prolonged exposure to damp conditions.

Preservation of Performance

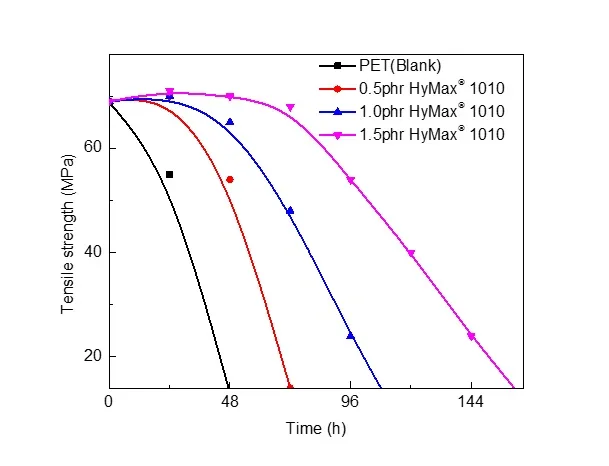

The preservation of performance is of paramount importance to outdoor enthusiasts who depend on their gear under challenging conditions. Hydrolysis-resistant agents play a pivotal role in maintaining the performance of polyester monofilaments by mitigating the loss of strength caused by water absorption. Polyester monofilaments treated with these agents retain their tensile strength and flexibility, critical attributes for activities such as climbing and rigging, even when exposed to moist environments.

Testing datas of anti-hdyrolysis agent in PET

Resilience against Adverse Weather

Outdoor gear frequently encounters a spectrum of weather conditions, ranging from heavy rain to high humidity. Hydrolysis-resistant agents guarantee that polyester monofilaments retain their structural integrity and performance even in adverse weather conditions. For instance, tent materials treated with these agents function as dependable barriers against rainwater infiltration, safeguarding campers from the elements and contributing to a comfortable outdoor experience.

Conclusion

The infusion of hydrolysis-resistant agents into polyester monofilaments used in outdoor gear heralds a significant advancement in product design and durability. By bolstering durability, safeguarding performance, facilitating effective moisture management, and reinforcing resistance to adverse weather conditions, hydrolysis-resistant agents have become pivotal components in the construction of outdoor gear polyester monofilaments. As technological progress continues, the symbiosis between hydrolysis-resistant agents and polyester monofilaments promises to redefine the benchmarks of resilience, longevity, and dependability in outdoor equipment, elevating the outdoor experience for enthusiasts worldwide.