How to choose the curing agent for printing adhesive paste?

Printing paste with curing agent can improve the adhesion of the printing coating, abrasion resistance, water resistance, solvent resistance, and touch feel. Choosing the

Printing paste with curing agent can improve the adhesion of the printing coating, abrasion resistance, water resistance, solvent resistance, and touch feel. Choosing the

TPU has outstanding abrasion resistance, bending fatigue resistance, and high elasticity, which can be used for various automotive parts. TPU contains many polar groups,

With the introduction of various environmental protection policies and the enhancement of consumer awareness of environmental protection, water-based products have gradually become the future

Polylactic acid (PLA) has many advantages so that it is currently used in packaging materials, 3D printing, agriculture, medical, textile, and other fields, most

In order to compete with other general-purpose resins and expand their application areas, manufacturers are constantly modifying PET engineering plastics. The modification focuses on

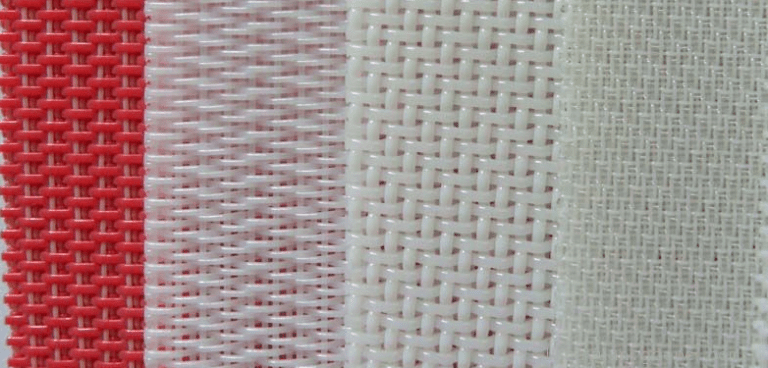

PET monofilaments have a series of advantages such as good impact resistance, wear-resistance and fatigue resistance, but PET is prone to hydrolysis aging and

Polyester polymer materials are prone to hydrolysis in humid environments, especially in humid and hot environments. A large number of terminal carboxyl groups are generated in

Polybutylene terephthalate (PBT) is a commonly used engineering plastic material with a series of excellent comprehensive properties, such as high crystallinity, rapid prototyping, weather

-768x441.jpg)

Water-based coatings are one of the trends in future development. Compared with traditional solvent-based coatings, water-based coatings have obvious deficiencies in adhesion to substrates,

We will contact you within 1 working day, please pay attention to the email with the suffix “@langyitech.com”.