In recent years, paper machine dryer screens have been developing very rapidly. Paper machine dryer screen is mainly used in the drying part of paper making machine, its main function is to transfer wet paper and dry the paper when transferring.

Because of its high strength, good air permeability and high drying efficiency, the paper machine dryer screen is more often used for ordinary packaging paper, which does not require high surface performance of paper.

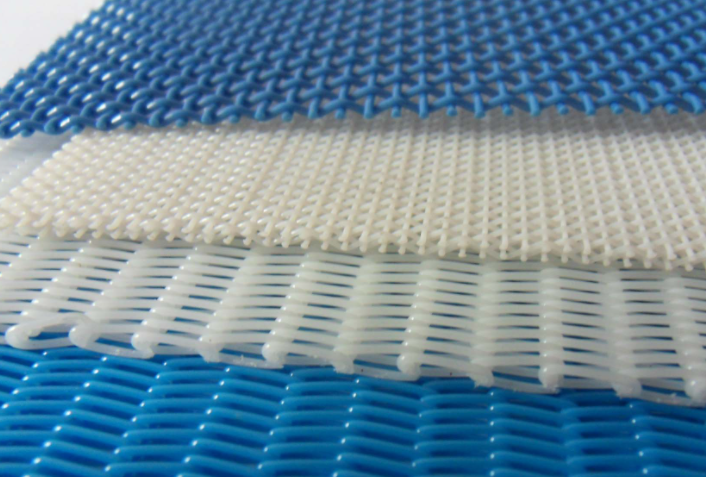

paper machine dryer screen

Main materials of paper machine dryer screen

The main material of dryer screen at present is polyester monofilament. As the polyester monofilament is divided into round monofilament and flat monofilament, the dryer screen is also divided into round monofilament dryer fabric and flat monofilament dryer fabric. From the application effect, the flat monofilament is better than round one. Flat monofilament can fit the paper more on the surface, reduce the trace on the paper. What’s more, it is easier to clean up the adhesives on the flat monofilament dryer fabric.

The performance requirements of paper machine dryer screen

1. Anti-pollution

In addition to the geometry of the wire to avoid dryer pollution, it is necessary to add fluorine substances in polyester materials to reduce its surface energy so that pollutants are not easy to adhere to the surface.

2. Anti-hydrolysis

The dryer is in a high temperature and high humidity environment. In addition, the PH value of some paper is not neutral. For these reasons, the corrosion of polyester material is very serious. Mostly, the end of life of the dryer screen is not caused by abrasion, but due to dryer fabric soiling or corrosion caused by the hydrolysis of the dryer fabric. To reduce the risk of hydrolysis, anti-hydrolysis agents are often added to the dryer fabric yarn to reduce this tendency.

The HyMax series of anti-hydrolysis agents developed by Langyi has been maturely used in polyester monofilaments of paper machine dryer screens for many years. The addition of anti-hydrolysis agents can make the dryer fabrics last more than twice as long and greatly reduce the consumption of paper machine dryer screens and the labor cost required to replace them.

Tips on the use of paper machine dryer screen

The joint is the weakest part of the dryer screen, so the strength of the threading and the dryer screen joining operation should be paid attention to. In addition, reducing the tension of the dryer, reducing the large wrapping angle of the dryer can also effectively avoid such problems. If the dryer fabric edges are poorly woven or hydrolysis occurs, it is easy to have problems with the edges throwing off the silk, which needs to be checked every time the machine is stopped.

Mostly, the operators think that dryer screen can be interchanged at will, here it should be noted that the manufacturer has made a certain match on the dryer design. The dryer screen in the high evaporation section often is added with hydrolysis agent. Therefore, unless there is a lack of spare parts, it is not recommended to switch the dryer screen at will.