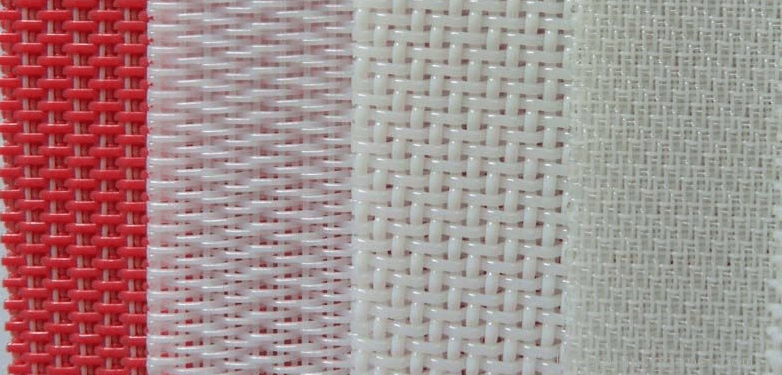

Application of anti-hydrolysis agent in PET polyester monofilament for paper making clothing industry

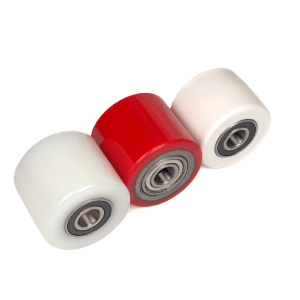

What is polyester monofilament? Polyester monofilament is made from PET chips. The chips are spun by melt method, then cooled and shaped in a bath, and finally drawn and thermoformed to get monofilament. Polyester monofilament is characterized by high strength, good toughness, dimensional stability, high temperature and low-temperature resistance, and chemical stability to acids and […]

Improve the performance of water-based polyurethane with carbodiimide crosslinker

With the introduction of various environmental protection policies and the enhancement of consumers’ awareness of environmental protection, water-based products have gradually become the future development trend of coatings and adhesives. Take water-based polyurethane as an example, it has the advantages of traditional polyurethane such as flexibility and low-temperature resistance. Since its main dispersion medium is […]

How to choose the curing agent for printing adhesive paste?

Printing paste with curing agent can improve the adhesion of the printing coating, abrasion resistance, water resistance, solvent resistance, and touch feel. Choosing the right curing agent system is essential for the application of printing paste. Taking the two-component printing paste system as an example, the commonly used curing agents are mainly the isocyanate system, […]

How to improve the anti-hydrolysis properties of TPU?

TPU has outstanding abrasion resistance, bending fatigue resistance, and high elasticity, which can be used for various automotive parts. TPU contains many polar groups, which can easily absorb moisture in the air. On the one hand, the absorbed water acts as a plasticizer, which will lead to a decrease in the physical properties of TPU, […]

The improvement of water-based polyurethane performances with carbodiimide crosslinkers

With the introduction of various environmental protection policies and the enhancement of consumer awareness of environmental protection, water-based products have gradually become the future development trend of coatings and adhesives. Taking water-based polyurethane as an example, its main dispersion medium is water. It has the advantages of traditional polyurethane such as flexibility and low-temperature resistance. […]

Hydrolysis-resistant modification of PLA

Polylactic acid (PLA) has many advantages so that it is currently used in packaging materials, 3D printing, agriculture, medical, textile, and other fields, most of which are disposable products or have relatively short use cycles. Commercial PLA itself has very obvious disadvantages, such as low crystallization rate, poor toughness, and non-flame retardant, which greatly limit […]

Modification of PET Engineering Plastics

In order to compete with other general-purpose resins and expand their application areas, manufacturers are constantly modifying PET engineering plastics. The modification focuses on the following areas: a) Improvement of formability. PET engineering plastics may crystallize rapidly at lower temperatures by selecting various nucleating agents and crystallization promoters to speed up the crystallization of PET […]

How to improve the hydrolysis resistance and service life of dryer fabrics in paper machine clothing?

PET monofilaments have a series of advantages such as good impact resistance, wear-resistance and fatigue resistance, but PET is prone to hydrolysis aging and failure under humid and especially hot and humid conditions. The paper machine dryer screen usually works under an environment of 100℃ containing water and gas. Because PET material is not resistant to […]

The difference between monomeric anti-hydrolysis agent and polymeric anti-hydrolysis agent

Polyester polymer materials are prone to hydrolysis in humid environments, especially in humid and hot environments. A large number of terminal carboxyl groups are generated in the broken polyester molecular chains after hydrolysis, and the terminal carboxyl groups will continue to catalyze the hydrolysis reaction. Finally, the polyester materials break due to hydrolytic aging. In order to improve the hydrolysis […]